Handplanes I Can’t Live Without

Do better work with these 8 vital hand tools.

Synopsis: Every shop needs handplanes, even those that rely heavily on power tools. There are just some jobs–such as smoothing a surface or fitting a joint perfectly–that you can’t do as well or as quickly with a power tool. With that in mind, Garrett Hack reveals his list of the eight essential handplanes. Learn why no woodworker should be without a No. 4 bench plane, two adjustable block planes, jointer, shoulder plane, smoothing plane, spokeshave, and small router plane.

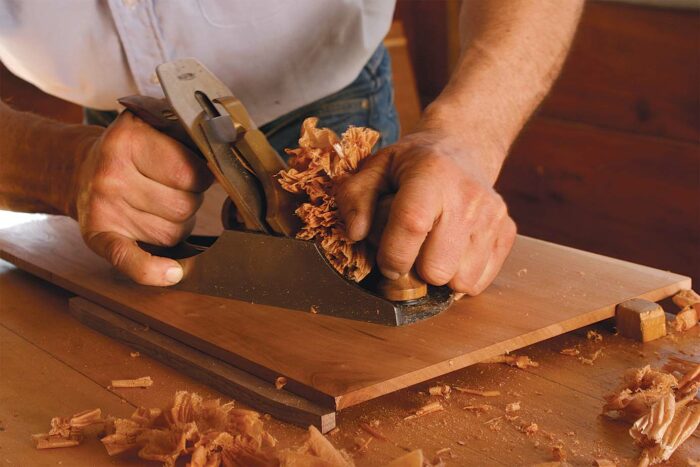

Every shop—even one that relies heavily on power tools—needs handplanes.

For some tasks, such as smoothing a surface or fitting a joint perfectly, handplanes fine-tune work that was begun on a machine. In other instances, they handle jobs that machines can’t do as quickly or nimbly. Handplanes are quiet, safe, and clean. They encourage working at a slower pace that is less prone to mistakes. And did I mention enjoyment? The swish of a plane across a surface and the smell of fresh shavings are reason enough to pick up a handplane.

To reap these rewards, though, you first have to spend some effort in learning to handle the tools and, most importantly, in learning to keep them sharp. A good guide for sharpening plane irons and other hand tools is David Charlesworth’s “A User’s Guide to Waterstones” (FWW #169, pp. 30-35).

The planes on this list are tools that I use day after day. Most do a variety of things very well; a few are the best tools for specialized tasks. I’ve listed them in rough order of importance.

Bench Plane

If you have just one plane in your shop, make sure it’s a No. 4 bench plane. I use mine all the time to flatten and smooth surfaces or to joint and trim edges in ways that power tools and sandpaper can’t.

If you’re fitting a drawer front, for instance, the plane lets you dial it in carefully, one 0.001-in.-thick shaving at a time. In contrast, a single mistake on the tablesaw can render the workpiece useless. You’ll also find that, with practice, you can use a No. 4 to smooth a fairly large drawer face with a few passes in less than a minute. Unlike a sander, the plane leaves a smooth surface that has deep clarity and is flat right to the edges.

The No. 4 also is great for cutting bevels in a profiled edge and does a respectable job smoothing end grain, like that on the edge of a tabletop. It even works well for shaping convex curves such as a bowed drawer front.

The key to the No. 4’s versatility lies in its middle-of-the-road size. It takes a two-handed grip that delivers enough power to flatten and smooth large parts, yet it’s small enough to use in tight places or for more delicate work. The blade can be adjusted to take a coarse shaving, or a very fine one that leaves a beautifully smooth surface.

You can tackle both tasks with a single No. 4 plane by opening the throat wide for the rough work, then narrowing the opening for the smoothing passes. For some No. 4s with a “Bedrock” frog, this adjustment takes 15 seconds; with others, the blade must be removed in order to adjust the frog forward and tighten the mouth.

Adjustable Block Plane

This plane, patterned after the Stanley No. 60½ , is another tool to keep within easy reach. Like the No. 4, it can be adjusted for rough or fine work, and it does a multitude of things well.

I like this plane for the precise trimming of small surfaces, such as where stile and rail meet on a frame. In similar fashion, I keep the No. 60½ handy when sizing small parts because it can take fine shavings from edges too narrow for larger planes.

For these reasons, the 60½ is perfect for the very exact business of sizing inlays and trimming them flush after glue-up, where the grain might be going in many directions. For the smoothest cutting in these situations, you need a plane with a throat that can be adjusted to the thickness of a piece of thin paper.

The block plane is also the best tool for trimming dovetail pins flush after glue-up. Because the plane cuts at a low angle, much like a paring chisel, it is ideal for cutting end grain smoothly.

This plane is also great for shaping wood, giving you great flexibility when cut-ting tapered chamfers or rounded edges. In contrast to a router setup, the block plane lets you refine or alter a profile easily as you go.

Jointer

|

Best at: Jointing edges of any length, flattening large surfaces

Model shown: Old Stanley Bedrock No. 607 Available new: Clifton, Stanley, and Lie-Nielsen all make a No. 7. |

I rely on the mechanical jointer in my shop every day, but I wouldn’t be with-out my jointer plane. The No. 7 is ideal for jointing edges on boards that are too long, heavy, or awkward to handle on the jointer. I often use it to clean up machine-jointed edges, especially those that will be glued. This is because jointer knives that are slightly dull or improperly set can create a scalloped surface that leaves gaps in the glueline. And that could mean a glue-line that shows or a joint that fails.

The No. 7 perfectly trues the edge and cuts a clean glue surface. I also can use the plane to make an edge slightly concave along its length for a sprung joint.

This plane and its beefier sibling, the No. 8, also are hefty and long enough to make quick work of flattening large surfaces or cutting a set of tapered legs dead straight. The long sole bridges valleys that a No. 4 would follow, making the jointer plane a better choice for flattening.

The accuracy of a jointer plane depends on a sole that is flat from end to end. These planes cost more to make and thus are considerably more expensive than a No. 4. Otherwise, look for the same basic characteristics: comfortable handles, a thick blade, and easy throat adjustment.

Shoulder Plane

I like to say that a perfectly fitted mortise-and-tenon joint looks like it grew together. Even with precise tablesaw tenoning jigs and hollow-chisel mortisers, though, it’s hard to get this sort of fit straight from the machines.

So many things can prevent a joint from fit-ting perfectly. A table-saw blade, even with stabilizers, can wobble and cut a shoulder that’s not perfectly straight. Or you could wobble when cutting the cheeks (even using a jig). You might have a joint ever so slightly out of square in either plane, in which case one shoulder hits before the other or the bottom hits before the top. The longer the shoulder (breadboard ends being the extreme), the more likely or more obvious the problems.

The shoulder plane fixes these slight imperfections, leaving you with a perfectly fitting joint. It can take a fine shaving precisely where you need it, whether on a shoulder or cheek. For slightly angled joints, a shoulder plane is safer than trying to use jigs, where it is very easy to get something backward and cut at the wrong angle.

I regularly use my Stanley No. 93 for adjusting rabbets cut by machine, such as on the meeting rails of two cabinet doors or when fitting a rabbeted panel. It also works respectably across the grain in other situations, such as sizing the bottom of a wide dado.

Smoothing Plane

Woodworkers smooth lots of surfaces. A smoothing plane is amazingly efficient at this, cutting flat surfaces so polished they shine with deep clarity. A No. 4 is an OK smoother, but it is a little light for really difficult grain. It’s more efficient to have a plane dedicated to smoothing. It should have some mass, a super-fine throat, and a solidly supported, thick blade. That No. 4 is still very useful as a pre-smoother, flattening a surface and doing the bulk of the work. That way, the smoothing plane need cut just a few gossamer shavings and stays at peak sharpness longer.

A good smoother may be the most expensive plane on this list, but it’s worth it. Among the best designs are heavy British planes such as those made by Norris and Spiers, with steel bodies infilled with dense rosewood, and very thick blades. A number of contemporary versions are available, some better than the originals. The heavy body and wide blade of the No. 4½ make it a very good smoother, especially with a 50° cutting angle (frog). Length is not important for a smoother, but some like the mass of a No. 7, No. 6, or No. 5½ for this work.

Spokeshave

|

Best at: Shaping, smoothing, and refining curves

Model shown: Old Stanley No. 52 Available new: Contemporary versions by Veritas, Lie-Nielsen, Woodjoy, and others |

For the most part, all of the planes listed so far work well to make wood flat, smooth, and square. But what about curves?

For shaping or smoothing curves, nothing beats a spokeshave. The spokeshave, with its narrow sole and winglike handles, doesn’t look like a handplane, but it works like one. It holds a relatively wide iron at a fixed angle and depth. It registers the cut against a sole, and it takes a shaving. The spokeshave’s long handles and narrow sole are ideal for steering around curves and working into tight places. They help maintain a consistent angle easily when cutting chamfers where a block plane won’t reach, such as along a concave curve. The narrow sole allows the tool to work both inside and outside curves. Soles come in a variety of shapes, including rounded for tighter curves. The spokeshave is a great tool for shaping the profile on the edge of a curved tabletop or an arched apron, or for smoothing the bandsawn profile of a cabriole leg.

A Second Block Plane

If you already have a No. 60½ tuned for precise work, you’ll find you can work more quickly if you set up a second block plane to make coarser cuts. Having twin block planes ensures that each is tuned precisely the way I want it for the work and spares me the hassle and variation of adjusting a single plane back and forth.

I use this second plane to rough out a wide chamfer or bevel, or to shape a bullnose profile for a cabinet molding. The plane offers good control despite making aggressive cuts. I also use my second block plane, set for a light cut, to remove freshly dried glue from a panel, a far safer bet than risking tearout by scraping it off.

Small Router Plane

When working on just a few parts, I often find that to set up a machine to do 100% of a task takes far more time (what with test cuts and jigs) than to do 95% of the job quickly and the rest by hand. A stopped groove for a box bottom is a good example. I can set up a tablesaw with a dado blade in a minute, but it leaves curved ends to be cleaned out. A small router plane is just the tool, with its right-angled blade projecting below the sole and working as a paring chisel. The blade can be locked to cut consistently at any depth. For a long time this was a shopmade tool, with a simple wooden body and a bent chisel blade.

The No. 271 router plane, the pint-sized sibling to the No. 71 router plane, is one of those planes that can make your life a lot easier. It can work in a groove or dado as narrow as ¼ in. wide, and it can work along a curve as easily as a flat surface. For leveling the bottom of an inlay recess, a router plane is far easier to use than a chisel, and less apt to damage the walls. It’s also useful for installing drawer locks that mortise into the back of the face, and for cutting hinge mortises at a consistent depth. The No. 271 is worth having for cleaning up stopped dadoes and sliding dovetails alone.

For the full article, download the PDF below:

From Fine Woodworking #195

Fine Woodworking Recommended Products

Veritas Precision Square

Bahco 6-Inch Card Scraper

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Log in or create an account to post a comment.

Sign up Log in