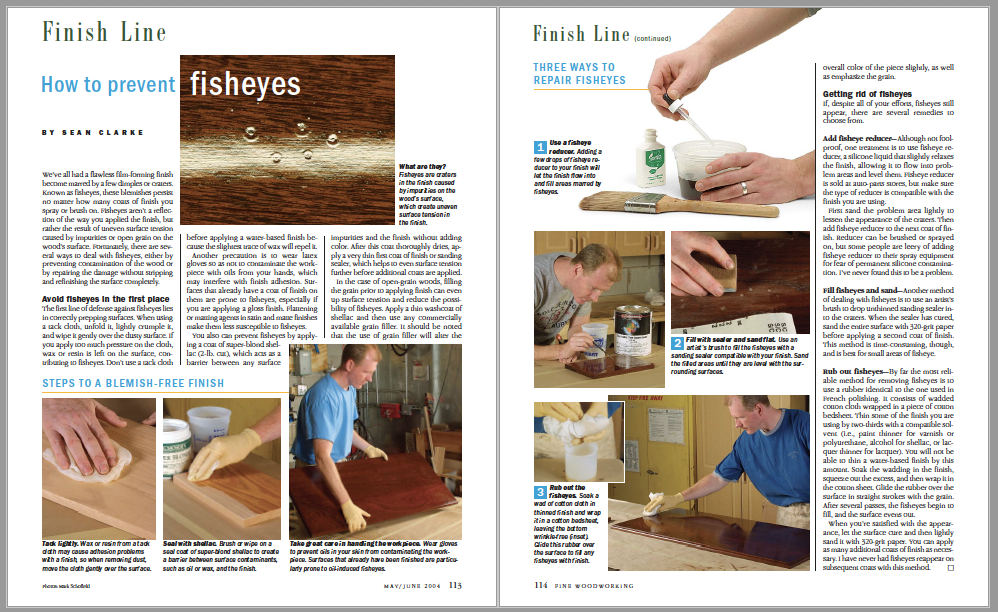

How to Prevent and Eliminate Fisheyes

With proper surface prep, you can ensure a blemish-free finish regardless of the application method.

Synopsis: Find tips to repair fisheyes and prevent them from showing up in your finish in this short article by woodworker Sean Clarke. These unsightly blemishes can show up on a film-forming finish if you don’t take the proper precautions. And if you already have the problem, Clarke offers three methods to make fisheyes disappear after the fact.

We’ve all had a flawless film-forming finish become marred by a few dimples or craters. Known as fisheyes, these blemishes persist no matter how many coats of finish you spray or brush on.

Fisheyes aren’t a reflection of the way you applied the finish, but rather the result of uneven surface tension caused by impurities or open grain on the wood’s surface. Fortunately, there are several ways to deal with fisheyes, either by preventing contamination of the wood or by repairing the damage without stripping and refinishing the surface completely.

The first line of defense against fisheyes lies in correctly prepping surfaces. When using a tack cloth, unfold it, lightly crumple it, and wipe it gently over the dusty surface. If you apply too much pressure on the cloth, wax or resin is left on the surface, contributing to fisheyes. Don’t use a tack cloth before applying a water-based finish because the slightest trace of wax will repel it.

Another precaution is to wear latex gloves so as not to contaminate the workpiece with oils from your hands, which may interfere with finish adhesion. Surfaces that already have a coat of finish on them are prone to fisheyes, especially if you are applying a gloss finish. Flattening or matting agents in satin and matte finishes make them less susceptible to fisheyes.

You also can prevent fisheyes by applying a coat of super-blond shellac (2-lb. cut), which acts as a barrier between any surface impurities and the finish without adding color. After this coat thoroughly dries, apply a very thin first coat of finish or sanding sealer, which helps to even surface tension further before additional coats are applied.

In the case of open-grain woods, filling the grain prior to applying finish can even up surface tension and reduce the possibility of fisheyes. Apply a thin washcoat of shellac and then use any commercially available grain filler. It should be noted that the use of grain filler will alter the overall color of the piece slightly, as well as emphasize the grain.

If, despite all of your efforts, fisheyes still appear, there are several remedies to choose from. Although not foolproof, one treatment is to use fisheye reducer, a silicone liquid that slightly relaxes the finish, allowing it to flow into problem areas and level them. Fisheye reducer is sold at auto-parts stores, but make sure the type of reducer is compatible with the finish you are using. First sand the problem area lightly to lessen the appearance of the craters. Then add fisheye reducer to the next coat of finish. Reducer can be brushed or sprayed on, but some people are leery of adding fisheye reducer to their spray equipment for fear of permanent silicone contamination. I’ve never found this to be a problem.

From Fine Woodworking #170

From Fine Woodworking #170

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Bumblechutes Bee’Nooba Wax

Bessey EKH Trigger Clamps

Foam Brushes

Log in or create an account to post a comment.

Sign up Log in