The Language of Finishing: Part 2

Understand the sometimes-cryptic terms that describe the different methods of applying and polishing a finish.

Synopsis: In part two of The Language of Finishing, learn the terms used to describe the process of preparing a surface for finishing, and applying the finish itself. From French polish to natural bristles, from orange peel to witness lines, learn these terms and you’ll not only finish like a pro, you’ll talk like one, too.

In FWW #229, I wrote about the often bewildering terms that woodworkers and finishers use to describe the task of preparing a surface for finishing, and for the finishes they use. As it happens, there are more linguistic land mines when describing how to apply a finish and how to give the surface a final polish. Understanding these terms will make you a better finisher, helping you understand your problems—and the solutions given by experts, too.

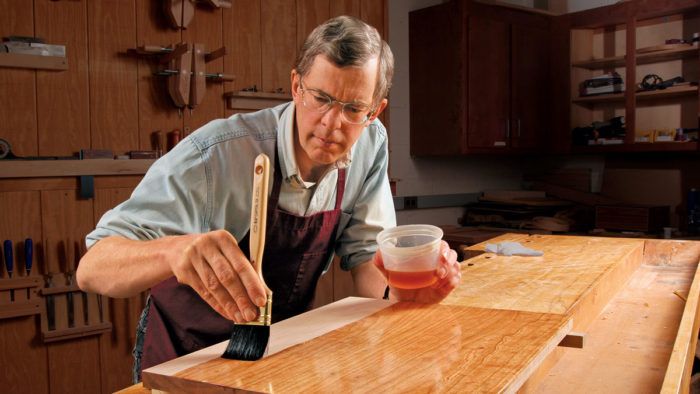

Wiping on a finish is a relatively simple process, but it’s not without pitfalls. I wish I had a dollar for every finishing article I’ve read that suggests using a lint-free cotton cloth. Many cotton items from socks to underwear contain lint—residual flecks of fiber that gradually come loose and disappear after multiple washings. That’s why an old, much-washed T-shirt makes a great application tool.

To check a cloth for lint, use it to dry a wine glass or clean a mirror with glass cleaner. any lint will show up on the glass and will mar your project if you use a linty cloth to apply a finish.

Aside from lint marring a wiped-on finish, you may also encounter a problem known as bleeding. This occurs with oil finishes on open-pored woods such as oak when excess oil oozes from the pores long after you’ve wiped the surface dry. If you don’t repeatedly wipe the surface, these droplets will dry into small, shiny dots that you’ll have to sand off.

One important wipe-on finishing technique is known as French polishing, in which a rubber (a pad made from several layers of cotton cloth) is used to apply the multiple thin layers of shellac that make up this classic finish.

All brushes have filaments—the individual strands, natural or synthetic, that make up the body of the brush. Only a few, though, have bristles, a type of natural filament made from animal fiber. These are typically made from hog bristle, also known as china bristle because that is where the material comes from. Other fibers used in natural-filament brushes include ox hair and badger hair. All work well for oil-based finishes, shellac, or lacquer. The natural resilience of the fibers allows them to hold a lot of finish and distribute it evenly. Avoid using natural-filament brushes for waterborne finishes, however, because the filaments will absorb water and lose their resilience.

To apply waterborne finishes, use a brush with manmade filaments or synthetic bristles. These are mostly made from nylon or polyester. A particularly fine-strand filament is called Taklon; these types of brushes are great for applying a thin topcoat that leaves almost no brush marks. Synthetic-bristle brushes can also be used for other finishes and many consider them almost as good as top-of-the-line natural-filament brushes.

From Fine Woodworking #232

For the full article, download the PDF below.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Foam Brushes

Diablo ‘SandNet’ Sanding Discs

Log in or create an account to post a comment.

Sign up Log in