Get a Grip on Your Work

For benchtop clamping, nothing beats the holdfast.

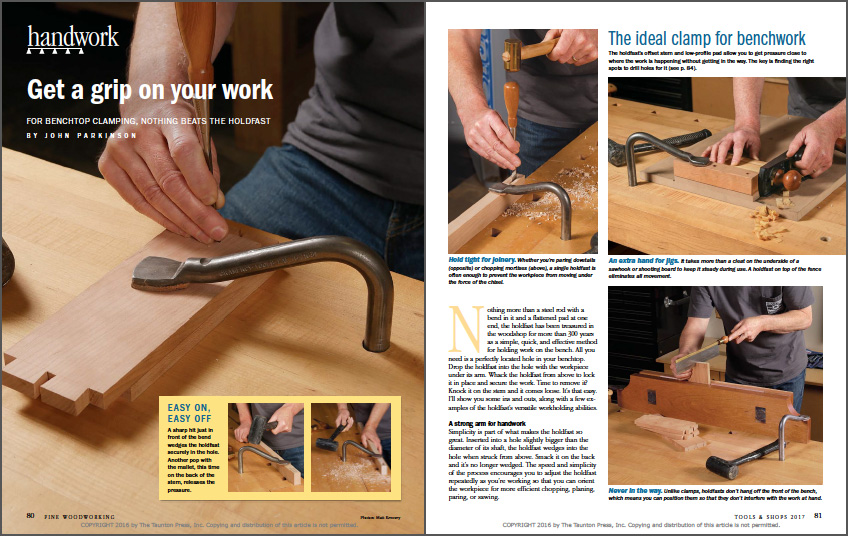

Synopsis: Simple, quick, and effective, a holdfast is simply a steel rod with a bend in it and a flattened pad at one end that is used to hold work on the bench. All you need is a perfectly located hole in your benchtop. Drop the holdfast into the hole with the workpiece under its arm. Whack the holdfast from above to lock it in place and secure the work. Time to remove it? Knock it on the stem and it comes loose. It’s that easy.

Nothing more than a steel rod with a bend in it and a flattened pad at one end, the holdfast has been treasured in the woodshop for more than 300 years as a simple, quick, and effective method for holding work on the bench. All you need is a perfectly located hole in your benchtop. Drop the holdfast into the hole with the workpiece under its arm. Whack the holdfast from above to lock it in place and secure the work. Time to remove it? Knock it on the stem and it comes loose. It’s that easy. I’ll show you some ins and outs, along with a few examples of the holdfast’s versatile workholding abilities.

A strong arm for handwork

Simplicity is part of what makes the holdfast so great. Inserted into a hole slightly bigger than the diameter of its shaft, the holdfast wedges into the hole when struck from above. Smack it on the back and it’s no longer wedged. The speed and simplicity of the process encourages you to adjust the holdfast repeatedly as you’re working so that you can orient the workpiece for more efficient chopping, planing, paring, or sawing.

Because the holdfast’s stem is offset from the workpiece, it’s rarely in the way of your tool. The clamping pad is low profile as well. You can place it close to the action and not worry about hitting it with a chisel or plane. Try that with an F-clamp. For such a simple tool, the holdfast applies a tremendous amount of clamping pressure. Under its grip, a workpiece or jig simply won’t move, and this makes working with hand tools easier and safer. Now you need some holes To use a holdfast, you need a hole through your benchtop. The key is making sure the holes are drilled square to the surface.

I’ve found that the easiest and safest way to drill holes for a holdfast is with another centuries-old tool, a brace equipped with an auger bit. Used in conjunction with a guide block, it drills a hole 90° to the surface of the benchtop with no trouble.

To make the guide, mill up a piece of stock at least 2 in. thick and long enough to reach more than halfway across the top’s width. At the drill press, drill a hole through the guide.

From Fine Woodworking #258

To view the entire article, please click the View PDF button below.

Fine Woodworking Recommended Products

Lie-Nielsen No. 102 Low Angle Block Plane

Incra Miter 1000HD

Starrett 12-in. combination square

Comments

Don't waist your money on any of these except the ones from tools for writing for working wood - they work the best and are the cheapest! Been using them for years.

I have a pair of the Grammercy holdfasts and can't imagine working on my bench without them. With a 3" thick top and 5" aprons, clamping to the bench top would be miserable with any other system. The holdfasts are VERY quick to use and the odd time one is really wedged in place, a whack from the underside of the bench frees it quickly. They also work great on the front of the bench as mentioned in the article.

Log in or create an account to post a comment.

Sign up Log in