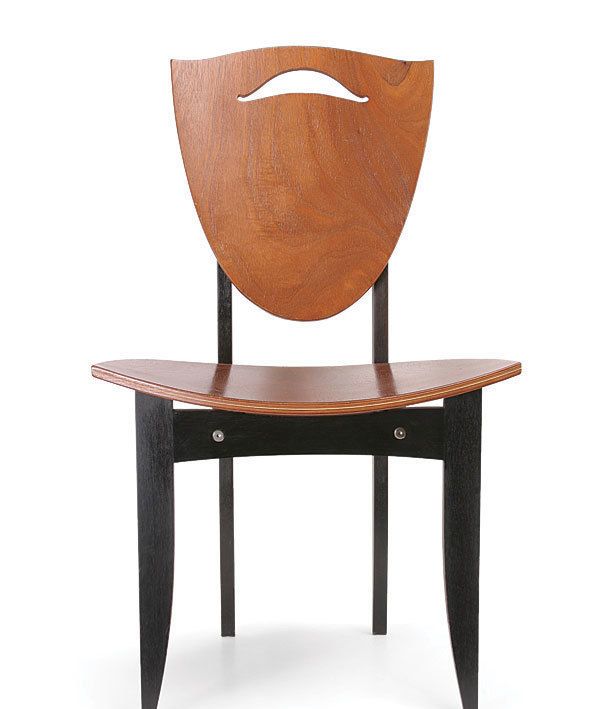

High-Design, Low-Price Chair

Michael Fortune's made-for-production chair.

Michael Fortune’s chairs run the price gamut, but as the sticker price comes down the time and effort invested have to do the same. In this $34 made-for- production chair, he also had to accommodate the limitations of manufacturing in a developing country.

Traveling from his studio in Canada to a community in Belize, Fortune provided on-site training, researched the materials available locally (keeping prices down and further boosting the local economy), and worked with the available machinery, which was often low-tech. The design of the chair as well as the production methods got pared down to the basics, and organization was the key to success. Fortune said he appreciated the challenges as a designer and craftsman, and most of the lessons he learned can be carried back into the one-man custom shop.

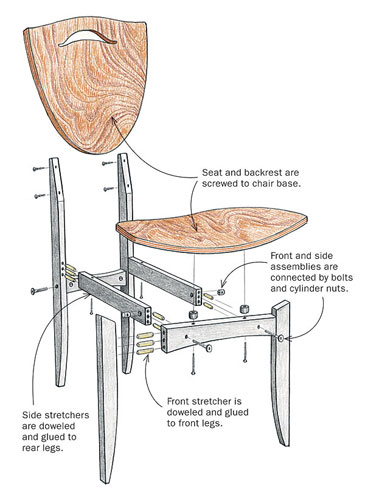

Packs flat—assembles easily

The chair had to be designed so it could be delivered as an RTA (ready-to-assemble) product. Dowels and bolts with cylinder nuts allow the product to knock down for flat packing and shipping, so the chair can be easily assembled at its final destination.

New life for an old machine

At the site, Fortune found a defunct overhead router being used as a storage table. Luckily, he was able to procure missing parts and rehab the machine so it could be used, with shopmade jigs, to cut the curved backrest and seat after they were laminated on a form.

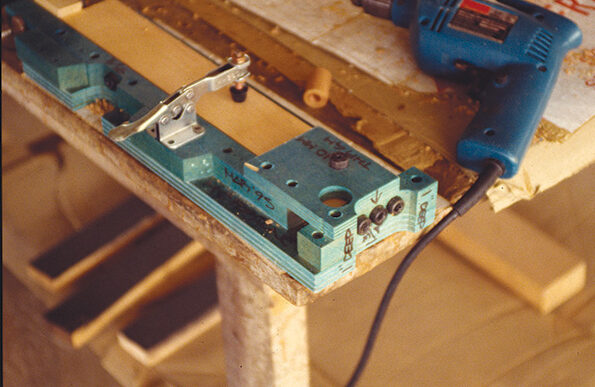

Jigs make joinery foolproof

The ready-to-assemble joinery was done with hand drills. A shop-made jig was clamped to a bench, and the workpieces set in place and drilled. To keep things fail-safe, all the jigs for this chair were color coded and precisely labeled. Then, multiple drills were set up with the bits at set depths.

Photos: Michael Fortune; drawing: John Tetreault

From Fine Woodworking #205

Fine Woodworking Recommended Products

Rockler Deluxe Panel Clamp

Trusty-Cook Dead-Blow Hammers

Log in or create an account to post a comment.

Sign up Log in