New safety considerations when using epoxy

An informative article from EHN sheds light on yet another alleged carcinogen in the woodshop.

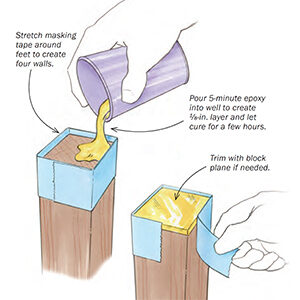

We’ve been talking about staying safe with chemicals lately, and thanks to a fantastic article from Environmental Health News (EHN.org), there’s one more workshop staple you should add to the list of things to take extra precautions with—epoxy resin. Whether you’re using resin for creative visual elements or if you’re like me and turn to it when you need a little bit of extra open time, it’s important to don a mask and gloves anytime you find yourself mixing “part a” with “part b.”

Everyone should read Meg Wilcox’s article, The hidden, potential cancer-causing, danger in woodworking and art supplies in its entirety. But I’ll give you some highlights in this post. You’ve likely seen the phrase “BPA Free” marketed on plastic foodware over the last few years. Well, it turns out BPA was the tip of the iceberg in regard to chemicals to avoid in the plastic-making process (yes, you’re making plastic every time you pour resin or epoxy).

“While beautiful, these resin materials are loaded with a dangerous hormone-disrupting, and likely carcinogenic, chemical called bisphenol-A diglycidyl ether, or BADGE. BADGE is similar to bisphenol A (BPA), an endocrine disruptor that can hijack the body’s hormone functions at tiny concentrations. BPA is linked to multiple health problems including cancer, diabetes, reproductive impacts, and behavioral problems, and is especially harmful to unborn and young children whose hormone systems are still in development.

“BADGE is far less studied than BPA, but its chemical structure concerns researchers because it includes reactive compounds known to cause cancer and other serious diseases. It is broadly used beyond artisan woodworking, such as in glues, boat repair and refinishing, in powdered coatings in automotive and other metal finishing, and in can linings. Zero workplace exposure limits on BADGE leave the door open for potentially harmful worker exposures, and sketchy, or even false, advertising about the safety of woodworking and art supplies. Researchers worry that the failure to adequately test and regulate BADGE leaves scores of workers, artisans, and individuals at risk.”

So how likely is it that your favorite epoxy uses BADGE? Well, if you can find the material safety data sheet at all, it seems pretty likely that you’re dealing with heavy amounts of BADGE in your epoxy.

“BADGE is the most widely used epoxy resin, with an annual U.S. production of several million tons. EHN’s review of epoxy resin kits sold online and in stores found just nine of 16 brands provided material safety data sheets (MSDS). Out of these, all but one, which blacked out its chemical ingredients, reported their resins contained BADGE at concentrations as high as 70% to 100%. Many resins also contain nonylphenol, another endocrine disruptor.”

But what does this mean to woodworkers? Well, it’s definitely something to take seriously, especially if you’re pouring large amounts of epoxy for resin art and resin tables, or you’re a pro who uses epoxy frequently.

“‘It’s like “BPA’s insidious alter ego,’ Patricia Hunt, Meyer distinguished professor in the School of Molecular Biosciences at Washington State University, told EHN. ‘It disappears, or turns into something else, and we don’t know what the metabolites are.’ …

“Despite these warning signs, there are no regulations for workplace exposure to BADGE, and the Food and Drug Administration continues to allow both BADGE and BPA use in can linings, arguing that exposure levels are low and that the chemical clears the body rapidly when ingested. An FDA spokesperson pointed EHN to its policy on approving food contact materials and said the agency ‘is not aware of any new information that has raised concern about the safety of BADGE under its intended use …’

“When BPA is breathed in or absorbed through the skin, however, Hunt said her research shows it gets into the blood and lingers. And that’s how woodworkers would be exposed—through skin contact when mixing and pouring the resin materials, or by breathing in dust when sanding the cured plastics.

“’As you sand … you’re probably getting a nice coating on your body, some of which is making its way into your body” even if you’re using a vacuum system on the wood dust,’ said Hunt.

“Fully cured resins in theory would not release BADGE when sanded, at least in the short-term, but ‘very few reactions are ever 100 percent complete,’ said Collins. That residual BADGE could become airborne on dust during finishing.”

Wilcox interviewed woodworking teacher Palo Coleman who works with resin frequently and teaches classes utilizing resin at a Rockler store in Cambridge, Mass.

“’In woodworking, the assumption is that everything’s carcinogenic,’ he told EHN. ‘That’s why it’s just best to use best practices whenever working with any chemical.’

“Best practices for Coleman, who has taught at Rockler for five years, means mixing resins outside in open air when possible, not mixing large portions at once, wearing personal protection equipment, and waiting at least a week for the materials to cure before he sands …

“’They never tell you on YouTube that [uncured] epoxy will harden in your lungs, because it hasn’t cured yet. All these people who sand it the next day, if they’re not wearing hazmat suits, it’s really dangerous,’ said Coleman, pointing to a wood piece with a deep vein of resin that had yet to cure from the week before because it hadn’t been mixed properly. As an experienced woodworker, Coleman can tell when resin is completely cured, but that may not be the case for people doing projects at home.”

There is still a lot to be learned about BADGE, and you should absolutely read Meg Wilcox’s full article. For me, even though I don’t use epoxy very often, I’m going to mix epoxy outside when I can, and I’ll be sure to use a respirator and nitrile gloves. I certainly am not swearing off using epoxy like some might, but it’s easy to be a bit more careful, and it costs nothing.

|

Where to buy denatured alcohol? |

|

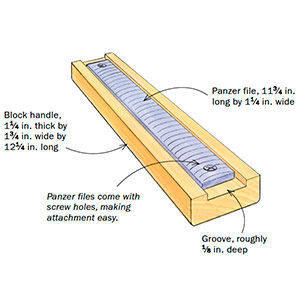

Eco-friendly composite materials |

|

Finish Recipe: Arts and Crafts Look Without Harsh Chemicals |

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Festool Cleantec CT 26 E HEPA Dust Extractor

MicroJig Matchfit dovetail clamps

Comments

Shoutout to Fine Woodworking for posting this kind of thing and to finish companies for striving to do better.

This chemist say thanks Fine Woodworking. A great post!

Same here. Thanks. Two other things I've seen mentioned in the past, as a chemist, that I would avoid are: using chromium to oxidize wood (FWW had several follow up letters to the editor when that article was published), glues containing formaldehyde which I've seen come up for veneer work.

Log in or create an account to post a comment.

Sign up Log in