Threaded rod and epoxy: A versatile option for leg joinery

Tim Coleman adapted a technique used with wooden dowels for a cleaner way to join legs to benchtops or tabletops without the need for aprons.

Synopsis: Seeking an alternative to the traditional mortise-and-tenon, Tim Coleman adapted a technique used with wooden dowels for a cleaner way to join legs to benchtops or tabletops without the need for aprons. He used a simple shopmade drilling jig and a hand drill to cut perfectly mating holes in parts that meet at odd angles. The combination of steel threaded rod and epoxy can create very strong joints in unlikely places.

I love wood-to-wood joinery, and the mortise-and-tenon joint, or some variation of it, is at the foundation of many of my tables, chairs, and cabinets. But in building a recent bench I found myself seeking an alternative to the traditional mortise-and-tenon. The bench would feature some extra-curly maple, and I decided to limit structural components for a clean, minimalist look. This meant no aprons to join the legs, and no intermediate stretchers to brace them. A long seat, and four legs. That’s all.

At first thought, the joinery seemed straightforward. The legs were beefy and the seat was 1-5⁄8 in. thick where the legs join. Plenty of room for two side-by-side floating tenons. Using my slot mortiser (or Domino, or router) I could cut mortises in the legs and seat in a jiffy. But there was a complication. The bottom of the seat is curved, and the legs are rotated so their outside faces aren’t parallel with the edge of the seat. Cutting the seat mortises on an angle would be unwieldy and inaccurate using my slot mortiser, and if I used a router or Domino instead, I would need a custom jig setup.

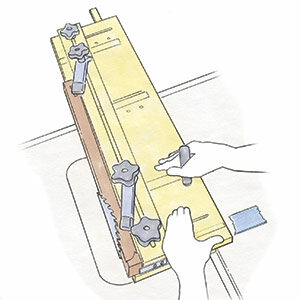

Hoping for joinery that would be simpler but no less durable, my thoughts turned to dowels. I could make a simple drilling jig to guide the bit when cutting holes in the legs and seat. This would be an efficient and economical solution. But I was concerned about the strength of wooden dowels, even with four in each leg. I have seen wooden dowels loosen or break when a joint such as this is subject to a severe lateral blow.

The solution came in the form of 3⁄8-in. threaded steel rod instead of wood dowels, and slow-set epoxy for the adhesive. The epoxy gets in and around the threads and creates an incredibly strong and durable bond. And unlike wood dowels, the steel rods can withstand the most severe forces. This was a joint that I felt confident would hold up over time.

From Fine Woodworking #285

From Fine Woodworking #285

To view the entire article, please click the View PDF button below.

|

|

|

|

|

Dining table shows off its joineryExposed joinery, echoed shapes, and elegant curves on display |

Fine Woodworking Recommended Products

Veritas Standard Wheel Marking Gauge

Pfiel Chip Carving Knife

Festool DF 500 Q-Set Domino Joiner

Comments

To make sure i understand, are the holes threaded also for the threaded metal bolts or is it just a regular hole and the epoxy joins it all together with any gaps?

Log in or create an account to post a comment.

Sign up Log in