Two Block Planes Are Better than One

Furniture maker Garrett Hack uses an apron plane for coarse work and then switches to an adjustable-mouth block plane for fine-tuning.

Synopsis: Garrett Hack keeps his two favorite two block planes close at hand whenever he’s working. He uses his Veritas apron plane set up for a thicker cut to remove the bulk of the material, and then switches to a larger, Lie-Nielsen No 60-1/2 to take thin, delicate shavings.

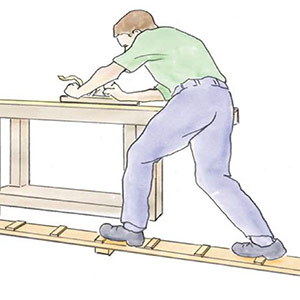

Every handplane has its own personality. It may take a few months to figure out, but once you discover what a plane does really well, how best to tune it, how tight the throat can be, and which bevel angle works best on the blade, the tool really begins to sing. This is certainly true of my two favorite block planes, which are always close at hand. The larger, a lie-Nielsen No. 60 1⁄2, is set up to be precise. It has an adjustable mouth that I keep tight, a firmly bedded blade, and ample weight, making it perfect for taking thin, delicate shavings. The other, a small Veritas apron plane, is set up to take thick shavings. It has a wide throat, is light in my hand, and is nimble, three features that make it a snap to work the plane quickly. But I don’t think of these block planes as independent tools. Rather, they are a complementary pair that work great together. I use each to its strength. I call the apron plane into service first, using it for rough work, getting things close. Then, I set it aside and pick up the adjustable-mouth block plane to take the last few, delicate, shavings. By the way, I keep both blades sharpened at an easy-to-maintain 25°.

Refine curved parts

Whether it’s been cut at the bandsaw or bent with steam, a curved part needs to be cleaned up and faired to look its best. Set up to remove wood quickly, an apron plane is the perfect tool to get rid of machine marks and the rough grain left behind by steam. It’s also a great way to dial in the curve’s shape. When it’s time to make the last small adjustments to the curve and smooth the part’s surface, set down the apron plane and pick up the adjustable-mouth block plane.

Create custom edge profiles

When you’ve worked hard to make a table or cabinet, it’s a shame to finish it off with a routed edge. A custom edge profile is more suitable for handmade furniture and is no trouble to make. Rough out the shape quickly with the apron plane, and then tune its shape and smooth its surface with the adjustable-mouth block plane.

Knock out chamfers

There are many ways to cut a chamfer, but none are as flexible as a block plane. You can cut a straight chamfer, one that tapers in width, and even chamfer around a curve. Do the bulk of the work with the apron plane. You might get some tearout, but don’t worry. The adjustable-mouth block plane, with its fine shavings, will remove it.

Trim inlay flush

After gluing a piece of stringing into its groove, quickly work it down near the surrounding surface with the apron plane. Speed is what you’re after at this stage. Then use the adjustable-mouth block plane to trim the stringing flush with the surface. But don’t stop there. Take another pass or two to smooth the inlay and the surrounding wood. With its tight mouth and the light shavings, the adjustable- mouth plane can handle even reversing grain and multiple inlay in one area.

From Fine Woodworking #255

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Micro-Adjust Wheel Marking Gauge

Olfa Knife

Lie-Nielsen No. 102 Low Angle Block Plane

Log in or create an account to post a comment.

Sign up Log in