Reversing Lathe Rotation for Sanding

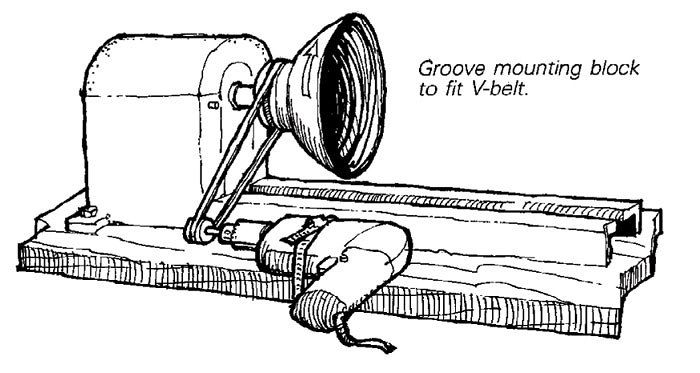

Here’s how I reverse the rotation on my lathe for sanding turned bowls. This approach reduces the problem of the faceplate unscrewing from the spindle, as often happens if you reverse the motor or the drive belt. After the bowl is turned, I cut a pulley groove in the glue block. Then I chuck a plywood pulley mounted on a 1/4-in. bolt into my electric drill. I mount the drill to the lathe bed and use a small V-belt to turn the bowl in reverse rotation.

Be sure to remove the lathe’s drive belt before starting up the drill. Otherwise, the drill motor would be fighting the inertia of the heavier lathe motor. This method will work on stock held between centers, too. Just leave enough waste stock at one end for a pulley groove.

Lawrence A. Fortier, Pleasant Ridge, Mich.

Fine Woodworking Magazine, October 1983 No. 42

Fine Woodworking Recommended Products

CrushGrind Pepper Mill Mechanism

Incra Miter 1000HD

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in