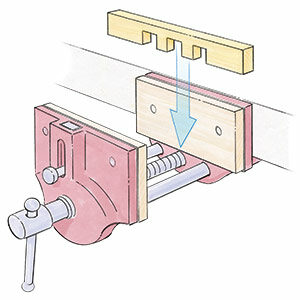

Hovarter bench vise mechanism has smooth, fast acting motion. Transfer bar synchronizes clamps.

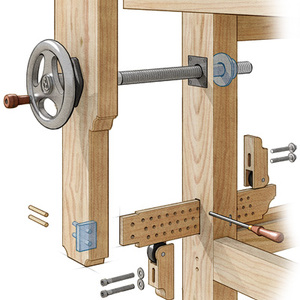

Every once in a while you find somone who doesn’t necessarily reinvent the wheel, but they rearrange existing technology into a forehead slapper that puts a whole new spin on that old wheel. Len Hovarter, a mechanical engineer from Michigan, has done just that with his new quick-acting threadless bench vise. You read that right, there are no threads involved with this vise. The clamping action relies on a wedge-like operation controlled by a geared wheel acting on the smooth shafts of the vise. A toothed transfer bar, mounted under the benchtop, synchronizes the clamping action on the two shafts, allowing one handle clamping, just like a chain-linked screw style vise, except this vise has the luxury of quick-acting slide rods.

Inspired by a workbench built by Mike Dunbar for an article in Fine Woodworking issue #153 (Tools & Shops 2001), Len decided that there had to be a faster method of moving the front vise jaw than tediously turning a couple of 1-3/4in. diameter wood screws. He started designing a quick release/ sliding rod mechanism that would eliminate all the cranking, but his first efforts were a bit off the mark. The clamp mechanisms were physically too big and heavy and the vise needed three rods, two to guide the vise and one for the clamp. Undeterred by this less than ideal start he continued working on the design, refining and improving the parts until he arrived at the current configuration. Len claims that his patent-pending design’s clamping action is identical to a traditional vise, the higher the pressure applied to the handle the higher the force applied to the workpiece.

Tapered work is easily and securely held in place and clamping stock at one end of the vise doesn’t need a second, identical piece to space the other end, the vise will accommodate the offset. With a bit of disassembly/ reassembly work the rotation of the vise handle can be changed for those who like to fly in the face of conformity.

Originally, Len’s plan was to produce most of the parts himself but initial interest in the product has raised the bar and he is now settiing up outside vendors to help produce parts to Len’s sringent quality demands. Len can also customize the vise for special purposes.

The vise kit should be available in September with a price in the mid-three hundred dollar range.

Future versions will be available with single-handle operation for tight quarters. Len is also well along with his prototype design for a leg vise that utilizes the same hardware but has a little twist to make it perform. As the vise is clamped against a workpiece the upper clamp pulls tight while the bottom clamp pushes away providing parallelogram clamping much like the action of a handscrew clamp.

I have a set of the hardware on order and I’ll give it a thorough thrashing as soon as I get my hands on it. I’m planning on building a new bench for myself this fall, so if the vise passes muster it will be incorporated into the design, and maybe Len’s leg vise too.

Watch for updates and a full test.

Roland Johnson

Follow him on Twitter: @Toolwriter

Comments

Nice to see someone take an old idea and reinvent it. Hope it works as good as it sounds.

Looks awesome! Can't wait to see it in person.

If this works it might be worthwhile building a whole new bench around it.

The price (mid 300's) seems high to me, but it would solve a lot of bench clamping problems. I hope that FW can find a way to trace this invention.

Slowlearner has an excellent point. My current bench isn't even finished but I would happily drop the plans to install Lee Valley's twin screw if this one pans out. It looks really slick and installing bench dog holes in the front would be child's play.

Slowlearner... Good suggestion... we're always looking for good workbench ideas. I'll keep this in mind as we plan future workbench projects. Gina

So it looks like the vise is out now--when do you guys think that you'll post a full review (covering the install and use)? A bench designed around the vise sounds great, but I would like a review to help me decide between the Hovarter and the Veritas vise.

I'm assuming a review is not going to happen at this point? Clicking on the hovarter keyword only produces this one article.

Log in or create an account to post a comment.

Sign up Log in