Four Hand-Tool Approaches to Side Beads

Bill Pavlak provides four hand-tool approaches to classic molding.

For a simple and effective way to enliven an edge, cabinetmakers have long turned to the humble bead. This rounded-over edge, set apart from the adjacent flat surface by a quirk (a deep narrow channel), adds an elegant interplay of shadow and light along the edges of pieces like straight table and chair legs, face frames, drawer fronts, and shiplapped backboards. There are many ways to sink a side bead into a board with hand tools, and they range from super cheap to very expensive. Here’s a look at four of them.

Screw stock

Primitive yet sophisticated, this is the easiest tool you’ll ever make. A screw in a small scrap of wood, it takes five minutes to make, is easy to use, and does an excellent job at cutting half a bead.

Among the cheapest and most clever tools in existence, the screw stock is simply a slotted wood screw protruding a desired distance from a scrap of wood—that’s it. Just secure the screw into a block of wood and file the head of the screw flat.

The screw stock’s virtues—cost and the precise adjustability of the screw height—are offset by the fact that you only get half of a bead; the slot cuts the quirk while the underside of the screw head compresses the wood to form the inner half of a bead. Sometimes I find that the shadows that gather in the quirk add enough visual interest that a full bead is not necessary. But when I want one, I’ll use a file or block plane to quickly round over the outer edge.

Scratch stock

Scraps of metal and wood come together in an affordable, shopmade beading solution.

A screw stock is likely the only tool that could make a basic scratch stock seem pricey. Small beads with nice full profiles are easy to make with a scratch stock on straight and curved edges alike. You make the cutter by using a round file on scraps of steel harvested from old cabinet scrapers or sawblades. It will cut cleanest if both faces and its curved edge are polished on fine sharpening stones or sandpaper. The finished blade can be held in a scrap of wood with a sawn slot and a bolt or two. If scratch stocks have a downside, it’s their tendency—shared by most scraping tools—to struggle in softer woods.

Create the cutter. Use a permanent marker to lay out the shape of your bead on the scrap-metal blank. Secure the blank in a vise, and use a round file (at 90° to the blank) to create the profile. The scratch stock will cut in both directions, so hone both faces of the cutter on a fine stone. And hone the curved edge as well.

Prepare the holder. Draw a layout line on an L-shaped block, and then use a handsaw or bandsaw to cut a kerf along that line. At the end of the block, use a Forstner bit to cut a shallow countersink for a bolt head. Then drill a clearance hole for the bolt. Assembly. After sliding the cutter into the kerf in the handle, put the bolt in place, and tightly secure a nut on the end.

Using is easy. To cut a bead at the edge of a workpiece, set the blade next to the fence. Start with a few light passes, keeping the inside of the L (the fence) snug against the workpiece. For best results, experiment with the angle at which the blade engages the wood. To make a bead farther from the edge, flip the cutter and slide it over toward the bolt. Scratch stocks are versatile. You can make a variety of custom holders. To cut multiple beads on a rounded column, Pavlak made a holder that straddles the column. With the column in a fixture clamped to the bench, he cut a bead along its length, then slid the cutter to the next position and cut the next bead. |

Side bead plane

With an integral fence and depth stop, these planes are a treat to use, and it’s hard to argue with the consistent results.

Side bead planes are designed to do one thing and in one size only. Want a different size bead? Buy another plane. That said, they do their job very well and with great efficiency. The beauty of molding planes like these lies in their combination of a well-supported blade, which leads to cleaner cuts, and two user-friendly features—a built-in fence and a depth stop—that ensure consistency and ease of use.

The first drawback of beading planes is obvious: It can be expensive to buy one let alone a whole stable of them. New planes from top makers cost $250 or more, though user-grade antiques can be found for a fraction of that cost. While side beads are some of the easiest molding planes to use, they are among the fussiest to sharpen and maintain.

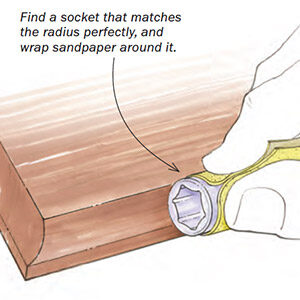

Sharpening a small beading blade. If the blade just needs honing, create a fine burr on the bevel by working its back through sharpening stones, finishing on a 10,000-grit waterstone. Remove the burr with a fine Arkansas slip stone. If it needs more than a quick honing, work the bevel aggressively with sandpaper around a dowel and then progress to the fine slip stone.

Set and use. Set your blade and wedge in place. These planes have a built-in fence and depth stop, so just keep the fence tight against your workpiece and plane the bead until the plane stops cutting. |

Combination plane

These planes were developed to handle a variety of tasks by simply changing the blade. They excel at beading.

Combination planes can be among the most expensive tools on both the new and antique tool markets. That cost is potentially easier to swallow when you consider the tool’s versatility; it can cut grooves, rabbets, beads, flutes, etc. While this jack-of-all-planes does not do everything well (I’m looking at you, cross-grain work), it excels at things like beads. The narrower beads preferred for furniture (1/8 in. to 3/8 in.) receive enough support from the plane’s adjustable bed for smooth cuts. The adjustable fences and depth-stops allow it to be used along an edge or further in on a workpiece with consistent results.

|

—Bill Pavlak is the supervisor at the Anthony Hay Cabinet Shop at Colonial Williamsburg.

This was originally a blog posted on Nov 15, 2023. Updated with new photos and more information Feb 20, 2025.

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Veritas Precision Square

Bahco 6-Inch Card Scraper

Log in or create an account to post a comment.

Sign up Log in