Workshop Tip: Trim edge banding on the router table

How to trim the excess banding flush without cutting through the thin veneer on plywood? The trick is to raise the fence.

I recently had a cabinetry project that required me to add edge banding to more than 100 ft. of plywood. As always, the challenge was to trim the excess banding flush without cutting through the thin veneer on the plywood. The usual method is to rest a handheld router on the narrow edge of the panel, with a flush-trimming bit hanging down to trim the overhang. It’s a wobbly setup, and if you mess up, you have to remake the panel.

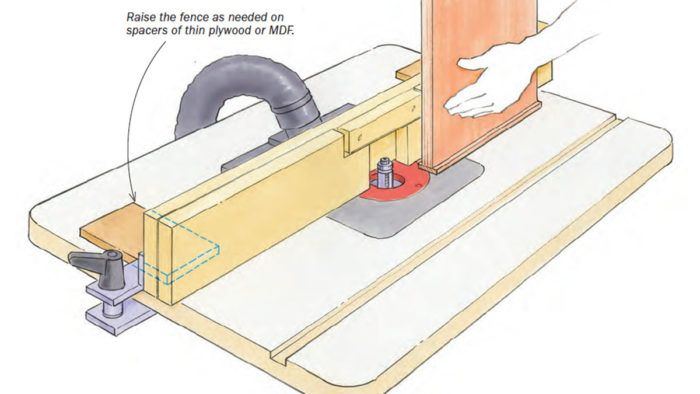

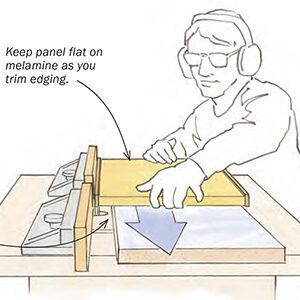

I found a way to do the same task faster—with no wobbles or worries—on the router table, using either a flush-trimming bit or a standard straight bit. By the way, I used thin, pre-glued banding on this project, applied with a hot iron, but my tip will work just as well with thicker, solid-wood banding.

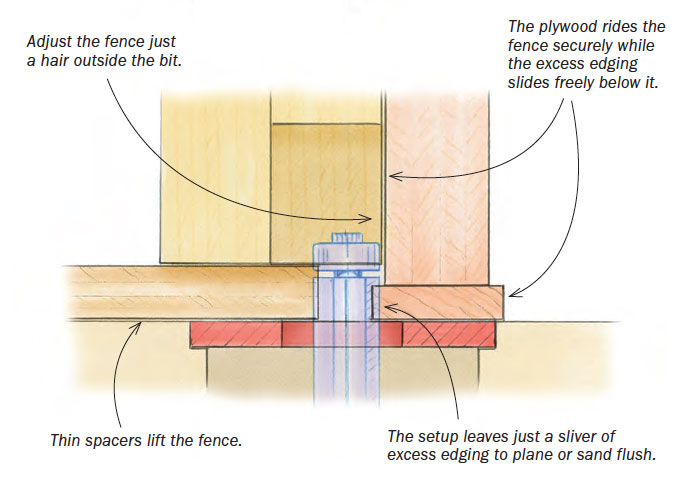

The trick is to raise the fence so the plywood panel can ride flat against it while the excess edging slides freely below. To raise the fence evenly, all you need is some thin plywood or MDF. Then you simply set the face of the fence a hair beyond the cutting arc of the bit, and make a test cut to be sure you’re leaving just a thin sliver of excess banding.

Be sure to keep the plywood pieces pressed against the fence as you slide them past the bit. After that, a lick with a block plane and/or a pass with a sanding block and 220-grit paper will bring the edging perfectly flush, making the whole panel look like solid wood. The setup is so quick and easy that I use it on edging jobs large and small.

—CRAIG HEISER, Atlanta, Ga.

Illustrations by Dan Thornton

From Fine Woodworking issue #283

|

|

|

|

|

Fine Woodworking Recommended Products

Grizzly G0495X Industrial Helical Cutterhead 8-in. Jointer

Rockler Dust Right 650 CFM

JessEm Mite-R Excel II Miter Gauge

Comments

I use a "curtain type" fence for almost all operations on the router table including this one. The outer part of the fence can slide up and down, I first saw this idea from Pat Warner. Main advantage as I see it is that I get an uninterupted surface to slide the wood against, no hole in the fence where the bit is and much better for small parts or end grain routing. Pats fence in link, mine in picture. The white fence is the one that can slide up and down, brown fence I almost never use anymore. https://s3.amazonaws.com/finewoodworking.s3.tauntoncloud.com/app/uploads/2016/09/05220454/rtf_opener.jpg

Log in or create an account to post a comment.

Sign up Log in