All About Dust Collection

Learn how to protect your lungs with top-notch dust collection tips and techniques.

In 2002, wood dust went from being a nuisance to an official health risk. That’s when the U.S. government put it on their list of “known carcinogens,” linking it to a variety of nose, throat, and lung cancers. But it has taken our corner of the woodworking industry a while to catch up with reality—in the form of the dust collector.

Collecting and exhausting dust at its source, before it reaches you, is the most efficient way to deal with wood dust. That’s why woodworking machines—from tablesaws to disk sanders—come with exhaust hoods or ports. “A typical exhaust hood,” industrial hygienist Richard Supples of Applied Improvement Technologies in Shelton, Conn., explains, “creates a capture velocity and effectively ‘grabs’ the dust particle and transports it through a duct/filter away from the worker.”

The trouble with older woodworking machines was that their exhaust hoods and ports were, at best, ineffective—and often nonexistent. But improvements have been steady and significant. If you are buying new machines or power tools, look for products that make dust collection convenient and effective. For your existing tools, take a day in the shop to improve the ports.

For more great tips on improving dust collection in older machines, be sure to see these articles from our archives:

Newer filter fabrics capture finer dust

Fifteen or twenty years ago, if you collected dust at all, you probably did it with a single-stage collector and a 30-micron polyester bag. Those porous bags act like fine-dust delivery systems, blasting out a cloud of the most dangerous stuff at head height. Ironically, the people who didn’t bother with dust collection at all, leaving big piles of sawdust under their tablesaws, were probably safer!

Not surprisingly, the most dangerous dust particles, the very fine ones, are also the most difficult to collect. Particulate smaller than 10 microns hangs in the air the longest, penetrates deepest into the lungs, and is the hardest for the body to filter and eject.

Tool companies eventually decided to get serious about filtration. Enter the pleated filter, which can pack hundreds of square feet of surface area into a small canister. That lets you get much finer filtration without killing airflow/suction. If you are in the market for a dust collector or shop vacuum of any kind, look for the ones that use a pleated filter. But let’s first talk about the power plant, the dust collector itself.

Why the cyclone dust collector is king

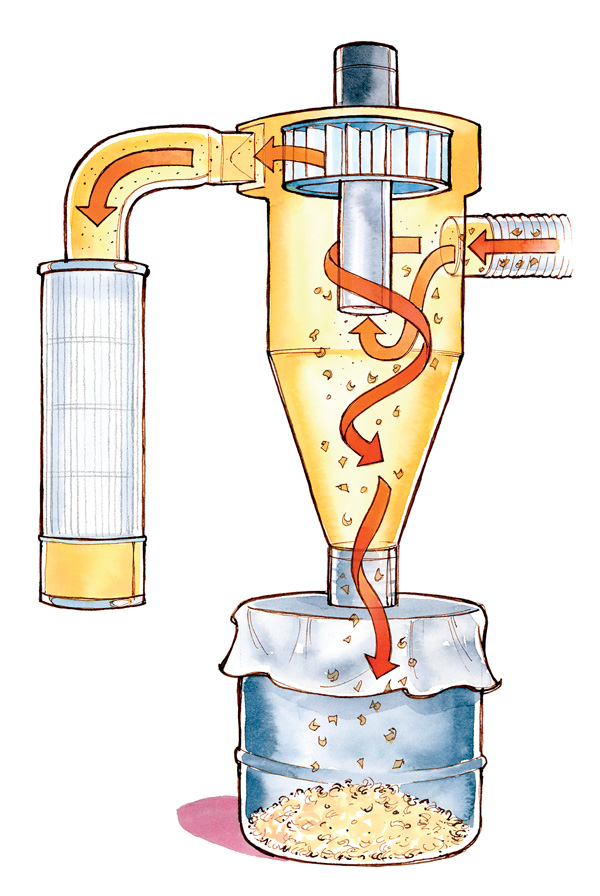

There are two main types of dust collectors: single-stage and two-stage. Two-stage collectors draw air first into a separator, where the chips and larger dust particles settle into a bag or drum before they reach stage two, the filter. That keeps the filter much cleaner and free flowing, improving suction. That means a two-stage system can accommodate a much finer filter than a single-stager, which is better for your lungs.

The most effective kind of two-stage system is the “cyclone,” which uses a funnel-shaped drum as the separator, or first stage. Dust spins around the outside, which gives bigger particles more of a chance to settle out before the smaller stuff escapes to the filter stage. If you can afford one, buy a cyclone dust collector. The first cyclones for small shops were big, expensive, stationary machines, requiring long hose or rigid-duct runs to reach all four corners of a shop; now, almost every cyclone manufacturer makes portable, roll-around models, and they’re as affordable as ever. Many are under $1,000.

Improving a single-stage dust collector

If you can’t afford a cyclone dust collector, buy the most powerful single-stage collector you can afford, with a bag or cartridge filter that will trap particles as small as 2 microns. Connect it to every machine in your shop. If it is big and powerful, you can connect it to multiple machines permanently, using a series of hoses and junctions, with blast gates to direct the airflow where you need it. With a smaller collector, you can roll it around and connect it to the machine you’re using. Long hoses sap suction, so keep the hose short with smaller dust collectors.

But be aware that the industry standard for filtration is 0.3 microns. If you want to get there, and truly clear the air, you will need a finer aftermarket filter for your dust collector. There are aftermarket models available from a number of manufacturers that will grab particles as small as 0.3 microns.

Keep in mind that these finer aftermarket filters clog quickly on single-stage collectors. If you don’t want to have to blow them out with compressed air each time you turn off the collector, you can add a separator stage, which turns your dust collector into a two-stage system. These are available in a couple of different types, from lids that go onto a trashcan to mini cyclones.

Get the most from your shop vacuum

Using a big dust collector is overkill for portable power tools like random-orbit sanders. They won’t easily go where the tool goes, and too much suction creates turbulence in a smaller dust hose or port, which chokes the flow and hampers effectiveness. This is where a shop vacuum comes in. The best new models let you plug your power tool right into the vac, so it starts up whenever you switch on the tool. Look for HEPA-rated filtration. If you own a shop vacuum already, you can upgrade its filter to HEPA. If the vacuum wasn’t designed for HEPA—with a filter shaker built in or an additional internal bag to collect the chips and dust before they reach the filter—your new HEPA filter will clog quickly, choking off airflow. The solution, again, is a separator, available from a variety of vendors.

Add a dust mask or respirator to your arsenal

Despite your best efforts, you will not be able to collect dust from every source. Miter saws are notoriously hard to collect from, and how do you suck up all the dust from hand sanding? In these cases, a snug-fitting dust mask or a respirator is your next best line of defense. Look for dust masks and respirators rated N-95 or higher. If you have a beard, a dust mask or normal respirator won’t make an effective seal against your face. In that case, consider buying a powered respirator. These keep a positive flow of air going past the face.

Air filters are controversial

Collecting hazardous dust where it’s coming out of the machine is the best way to protect your lungs. And experts agree that a respirator or a good dust mask is the next best thing. But those feel like a nuisance to some woodworkers, and many turn to ceiling-mounted air filtration units in an effort to clear the air.

There is some controversy among industrial hygienists regarding the safety of these ambient-air filters. According to Supples, they “transport the dust directly through/past the breathing zone of the machine operator thus creating more exposure risk than necessary.”

But other industrial hygienists we spoke to dismissed this argument. “If they’re well-placed and have quality filter media,” industrial hygienist Bob Cashins of Cashins & Associates in Wakefield, Mass., told us, ceiling-hung units “are good for getting rid of the hazardous dust.” If you’re going to use a ceiling-hung filter, manufacturers recommend placing it against a wall, where it can create circular airflow for maximum efficiency. Avoid putting them in middle of the room, above the tablesaw, or above the bench.

What no one disputes is that capturing dust at its source, with powerful suction and fine filtration, is the best way to clear the air in your shop.

More from FineWoodworking.com:

- Dust Collection for the Small Shop

- Workshop Tip – Quick-Change Dust Collection Manifold

- Dust Collection Demystified

- Soup Up Your Dust Collector

- Step Up to Whole-shop Dust Collection

Fine Woodworking Recommended Products

Rockler Dust Right 650 CFM

Festool Cleantec CT 26 E HEPA Dust Extractor

Comments

In the picture that shows a guy running a board through an open stand joiner, most brands of open stand joiners have the same type of dust collection setup, which in my opinion is not very efficient. So I redesigned and built a new dust hood for the JET open stand joiner that I had.I do have pictures.

I have a DC, an air filter and a good mask. So there.

The thing about the air filter is that when I do sanding or cutting of MDF/dusty stuff, I can turn on the air filter and it will take out the majority of dust that inevitably escapes the DC or vacuum cleaner attached to the tool.

None of them get 100%, even the mask. But with all things in your dust fighting arsenal that you can get, your chances of good lung health are better.

Great article and information!

I agree with what you said about aftermarket supplier. They are great if you can find a supplier/distributor that has quality products for better, cleaner air.

Log in or create an account to post a comment.

Sign up Log in