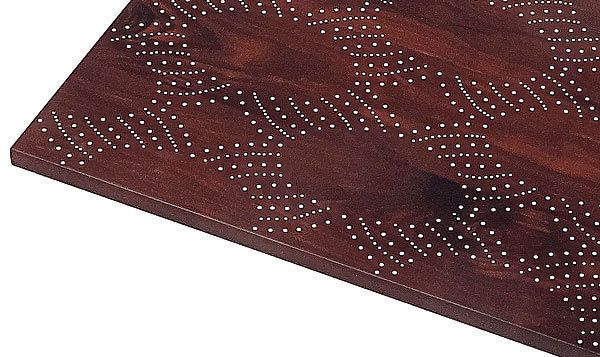

Decorative Nailing

Learn how Peter Sandback uses aluminum-siding nails to inlay intricate patterns on his furniture.

The decoration on Peter Sandback’s tables—made with thousands of aluminum nails—begins with images he finds of old dot-patterned fabrics. After photographing a sample of fabric and cropping the image to the shape of his workpiece, Sandback emails the digital file to his local office-supply store, where for just a few bucks they print it out at any size he needs. That printout becomes a full-size template that guides his drilling.

Sandback knew he wanted a rich, dark wood to contrast with the silver dots of his patterns. After experimenting with wenge (dark, but expensive and splintery), he found Cambia, a line of domestic hardwoods from Northland Forest Products in Kingston, N.H., that are baked to make them decay-resistant for outdoor use. The heating process also happens to darken the wood to a rich brown. This table is heat-treated red oak.

|

|

|

|

Applying the pattern. Sandback uses spray adhesive to affix his paper nailing pattern to the tabletop. Working one half at a time, he sprays on the adhesive, then uses a roller to press the pattern flat. |

How to drill a zillion holes. Drilling thousands of holes with his regular drill gave him a backache, so Sandback suspended a rotary tool over a portable worktable where he can drill sitting down. |

|

|

|

|

No hammer needed. After dipping them in polyurethane glue, Sandback presses the aluminum nails into slightly oversize holes. If the holes are too snug, he has learned, the tabletop will warp from the cumulative pressure. For this table, Sandback used nails of two sizes to create larger and smaller dots. |

|

|

Mow ’em down. Aluminum nails are easily cut with an angle grinder fitted with a cutoff disk. Sandback is careful not to dig into the wood. It takes him about five minutes to flush-cut the nails on a tabletop this size (left). Then, starting with 60-grit paper, he uses a random-orbit sander to sand away the paper pattern and smooth out the tabletop. |

|

|

The pattern pops. A coat of dewaxed shellac—followed by a topcoat of waterborne urethane— brings the dot pattern into sharp focus. |

Fine Woodworking Recommended Products

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Bahco 6-Inch Card Scraper

Comments

Beautiful innovative technique and I'm anxious to try it.

Log in or create an account to post a comment.

Sign up Log in