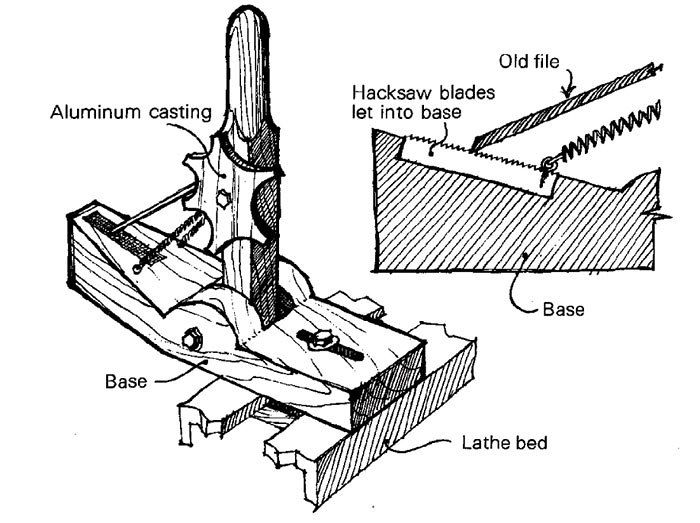

Two Steady-Rests

The homemade stabilizer device shown above allows me to turn four-poster beds and architectural columns on my 9-ft. lathe. The stabilizer eliminates the whipping and vibrating that accompany long-stock turning. The brace bolts to the lathe bed at about the midway point. A long upward-pointing handle is hinged to move the cast-aluminum stabilizer back and forth so it can ride against the stock. The stabilizer has several different diameters to fit different-sized turnings. The aluminum, coated with a little beeswax where it rubs, effectively carries away the heat. The brace adjusts against the stock through a spring-loaded device that moves an old file against a stack of hacksaw blades.

Deloe Brock, Chattanooga, Tenn

Here is an economical steady-rest made from three sections of a carriage bolt and two plastic casters (drawing, above). Cut and join the wood to fit your lathe bed, then drill the bolt hole the same height as the center spindle. The base clamps to the lathe bed and adjusts in or out for large or small work. The roller arm pivots on the bolt to provide a fine-tune adjustment to the changing diameter of the work in progress.

James Ulwelling, Coon Rapids, Minn.

Fine Woodworking Magazine, June 1981 No. 28

Fine Woodworking Recommended Products

Double Sided Tape

CrushGrind Pepper Mill Mechanism

Hedgehog featherboards

Log in or create an account to post a comment.

Sign up Log in