Drilling Angled Holes

For my early American reproductions, such as cobbler’s benches and step tables, I have found that splaying the legs about 5¡ in two directions is just about right.

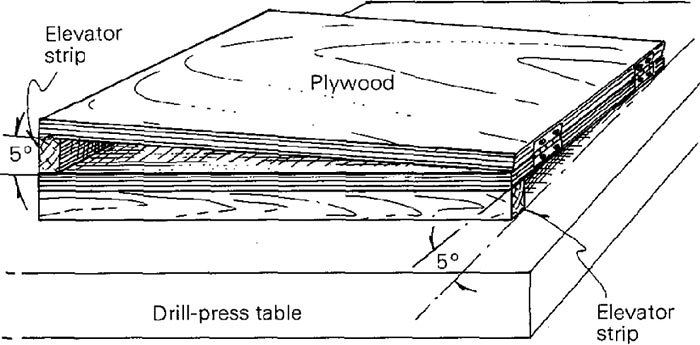

I recently made a simple fixture for my drill press for boring the holes in the tops of these articles. I used two pieces of 3/4-in. plywood, 18 in. square; to both pieces I fastened a strip of wood to give me the desired 5¡ angle. This then works as a compound sine block. The plywood squares are hinged together; if you want the holes flared in only one direction, fold the top piece out of the way.

To determine the height of the elevating strip, I multiplied the length of the plywood piece by the tangent of 5¡ (0.875) and got 1.575 in., or roughly 1-9/16 in. I then ripped one edge of two pieces of wood, 18 in. by 1-5/8 in. by 1 in., to get 1-9/16 in. After sanding down the inside edge, I fastened each of these flush with one of the edges of each plywood piece, and hinged the two pieces together, so the angles were at right angles to each other.

I cut the legs to length, with a double 5¡ angle on each end, before tapering and turning ends to fit holes in the tops. Of course, the angle can be changed by just multiplying the tangent of the desired angle by the length of the plywood pieces, and using the result for the height of the elevator.

Eugene Roth, Honeoye Falls, N.Y.

Fine Woodworking Magazine, Winter 1978 No. 13

Fine Woodworking Recommended Products

Forrest Woodworker II Blade

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in