All About Hollow-Chisel Mortisers

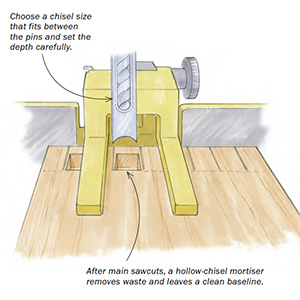

Hollow-chisel mortiser machines are really specialized drill presses that combine an auger with a hollow chisel to bore square holes. The auger removes most of the waste, while the chisel edges shear off remaining material on the sides of the cut.

What Counts:

• Motor size and maximum size of mortise

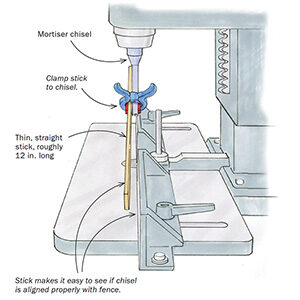

• Accuracy and easy of use for fence and hold-down system

• Maximum stroke

• Availability of tilting table for angled work

Mortisers make short work of this fundamental woodworking joint, and although the sidewalls of the mortise are not as smooth as they would be if machined with a router, the process is fast and easier to control. Chisels to make 1/4-in., 5/16-in., 3/8-in., 1/2-in., 3/4-in. and 1-in. mortises are commonly available from a number of suppliers.

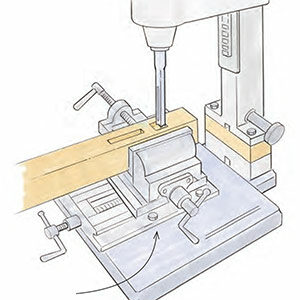

Benchtop hollow-chisel mortisers

Mortisers are available in several sizes, beginning with benchtop models that cost about $250. These machines typically have 1/2-hp motors and a stroke of about 4-3/4 in. They can comfortably handle 3/8-in. mortises in hardwood but may bog down when muscling through dense wood with a 1/2-in. chisel. Metal fences are adjusted by hand, which can require some finicky adjustments to get the mortise in exactly the right place. The fork-like metal hold-downs, designed to keep the workpiece from lifting off the table on the return stroke, can be balky.

Some companies also make 1-hp versions of these tools, with prices starting at a little over $400. The extra power makes it possible to cut bigger mortises, and these larger versions also have a slightly longer stroke, meaning they can handle thicker or wider pieces of stock. Work tables are a little bigger, but the fence and hold-down systems are essentially the same.

Freestanding hollow-chisel mortisers

At the upper end of the spectrum are freestanding mortisers. At about $1,000, these machines are significantly heavier, with motors that can run on 115v or 230v current. They’re capable of cutting mortises up to 1 in. They also have more sophisticated adjustment systems that make it much easier to locate mortises correctly, a longer stroke, and tilting work tables to make angled mortises.

How they work

The auger removes most of the waste during the cut, channeling it upward through the middle of the chisel and out the side through an ejection port. At the same time, chisel edges shear off remaining material on the sides of the cut. A long handle provides the necessary leverage through a rack-and-pinion guide system.

All of the machines work best with razor-sharp chisels whose outside walls have been carefully honed and polished. Augers should also be kept sharp.

More from FineWoodworking.com:

Fine Woodworking Recommended Products

Rockler Dust Right 1250 CFM

Grizzly G0495X Industrial Helical Cutterhead 8-in. Jointer

Log in or create an account to post a comment.

Sign up Log in