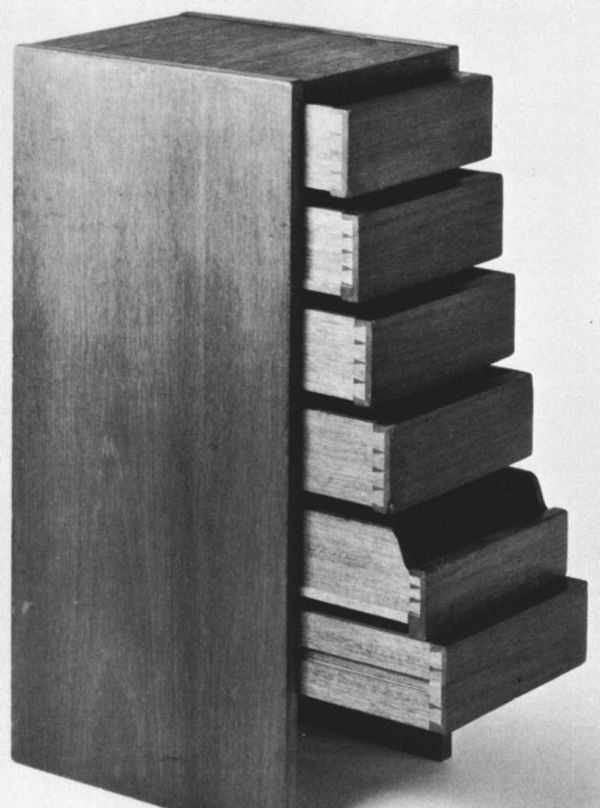

Synopsis: Alan Marks says drawers have long been considered one of the most difficult elements in cabinetry, probably with justification. The many types of construction possible using dovetails allow for innovation and flexibility, as witnessed by these six examples from Malmstens Verkstadsskola in Stockholm. All the front dovetails joints shown here are half-blind. The six examples include French bottom, false French bottom, kitchen, NK, NK ply bottom, and side-hung drawers.

Drawers have long been considered one of the most difficult elements in cabinetry, probably with justification. Done in traditional fashion, they are time-consuming and require exacting work if they are to operate properly. This accounts on the one hand for industry’s preference for stapled particle board, hot-melt glues, and ballbearing steel suspension glides; and on the other hand for the tendency of today’s craftsmen to avoid traditional drawers in favor of compartments, shelves or pigeon holes. Dovetailed construction, however, remains the strongest way of making a drawer, and also the most attractive.

The many types of construction possible using dovetails allow for innovation and flexibility, as witnessed by these six examples from Malmstens Verkstadsskola in Stockholm. Although the Swedes agree that the dovetailed drawer is the sturdiest, they often consider the decorative aspect incidental. All of the front dovetail joints shown here are half-blind. The conservative Swedes generally eschew through dovetails in drawer fronts because they interfere with the design requirements and overall style of traditional pieces. Drawer fronts on such cabinets often are delicately inlaid with veneers or carved or profiled around their edges, all unsuitable situations for through dovetails. Also, problems of uneven swelling and shrinkage can occur with through dovetails, when the wood of the solid drawer front shrinks while the end grain of the tails does not. Through dovetails are, however, used in the backs of drawers, where the unevenness ordinarily remains unnoticed.

French bottom

The traditional drawer bottom is made of solid wood, as opposed to Masonite or plywood. Thought to have originated in France, the so-called “French” drawer bottom floats with its grain running parallel to the drawer front, grooved into a two-piece frame formed by the glides. The drawer front is rabbeted to receive the bottom, which is slid home after glides have been glued to the drawer sides. Then the bottom is secured at the front with screws or a few brads, thus allowing later removal for cleaning, refinishing or repair, or else it is simply glued at the front edge. Either way, the wood bottom is free to expand and contract in its grooves. On a drawer this small, the bottom need be only 8 mm (5/16 in.) thick; it is raised 1-1/2 or 2 mm (1/16 in.) above the bottom of the glides to get around problems of sagging and scraping. The tongues should be made about 2 mm (3/32 in.) thick and 3 mm (1/8 in.) long.

More on FineWoodworking.com:

- Fitting Drawers – You don’t need a perfect drawer or case to get perfect results

- Illustrated Guide to Drawers – The ideal drawer? That depends. Here’s how to choose

- Stop Those Drawers – 6 techniques to keep drawers flush year-round

From Fine Woodworking #9

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Dubuque Clamp Works Bar Clamps - 4 pack

Log in or create an account to post a comment.

Sign up Log in