A Simpler Way to Offset Drawbore Joinery

Watch Mike Pekovich's one-step process for simplifying the task of offsetting drawbore holes by using an undersize center punch.

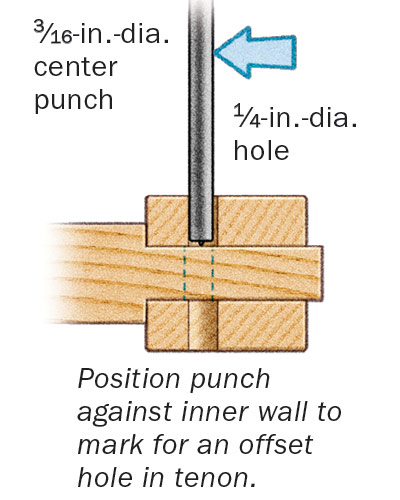

To create drawbore joinery, start by drilling holes through the mortise locations. Assemble the joints and mark each tenon for drilling. Use a center-finder punch with a smaller diameter than the hole (I prefer a 1/16-in. undersized) and register it against the inside wall. Drilling at the new mark will yield a slightly offset hole in the tenon. Chamfer the leading edge of the pin so that it clears the offset holes. When the pin is driven into the joint, the parts will pull together tightly with no need to clamp them for glue-up. The drawbore also makes it easy to dry-fit the parts to measure or check the progress of your shaping as you build.

To create drawbore joinery, start by drilling holes through the mortise locations. Assemble the joints and mark each tenon for drilling. Use a center-finder punch with a smaller diameter than the hole (I prefer a 1/16-in. undersized) and register it against the inside wall. Drilling at the new mark will yield a slightly offset hole in the tenon. Chamfer the leading edge of the pin so that it clears the offset holes. When the pin is driven into the joint, the parts will pull together tightly with no need to clamp them for glue-up. The drawbore also makes it easy to dry-fit the parts to measure or check the progress of your shaping as you build.

Check out Mike’s latest project in Fine Woodworking #280, coming 11/27/19!

|

|

|

|

|

Comments

I had trouble finding the center-finder punch online, but found them under the name of "Transfer Punch."

Definitely a V-8 moment once you see the video. Thanks, Mike.

I like the technique better than the 'manual' approach with the awl. But why spend the money on the center punches. How is that any better than using brad point pits to mark the spot?

I've been wondering if this technique could be used without glue. Any thoughts? Pros vs cons? Thx, Jeff

Jeff, medieval furniture used this technique And wedges without glue. It works Fine if the wood is dried properly.

Brad points and centre punches are both good ideas. The joint needs to pull in square. There’s not much leeway for adjusting squareness.

Thanks for your reply!

Can this technique be used with half-lap joints? How about angled half-laps?

Center punch idea is nice.

But I think Michael just gave new life to my brad point drill set.

Clean way of marking the offset hole. Nice!

However, this idea about the joint being pulled together with the drawbore has always struck me as wrong. If you've made the joint correctly the shoulder is already tight (pretty sure that's the level Mike works at, like the drawing in the article). In reality isn't it that the pin and/or the hole is being deformed as the pin is driven and that is then what locks the joint together? Not really pulling it together but locking it. I would like to see a cross section of the drawbore joint.

Paul Sellers has a video on his Youtube channel where he saws through the middle of a drawbored tenon and discusses the mechanical advantages of the joint. You should check it out.

Using a 1/16-under punch or brad point drill will offset the tenon bore center by 1/32, correct? (i.e. half the diameter of the punch/bit). That seems like an awfully tight tolerance -- is that typical of drawbores?

Log in or create an account to post a comment.

Sign up Log in