Ditch the math

Vic Tesolin shares his secret to measuring woodworking projects accurately: Start with some numbers, finish with none.

There is no lack of debate on the internet when it comes to woodworking. One of the most controversial is whether to use imperial or metric measurements. This is really only an issue in North America, as the majority of the woodworking world works in metric. I work in metric because I find it easier, but to be honest, I drop numerical values as soon as I can in my builds because if you want to work as accurately as possible, it’s advantageous to lose the numbers.

I have a tongue-in-cheek saying that goes like this: “Numbers lead to math, math leads to mistakes, and mistakes lead to drinking.” It’s meant to be humorous, but what isn’t funny is a critical error made on a project that could have been avoided by not using numbers or math to determine a component’s size.

So what’s a woodworker to do without numbers? Referential measurement is the solution in these cases. Imagine you’ve made a small box and you need to make a drop-on lid. The common method is to grab some sort of measuring tool like a rule, measure the opening, and then build the top according to those numbers.

Fun fact of the day: what’s the difference between a ruler and a rule? The graduations of a ruler generally start away from the end and a rule starts the graduations on the end. More often than not, woodworkers use rules instead of measuring tapes, as tapes are generally too coarse for fine woodworking.

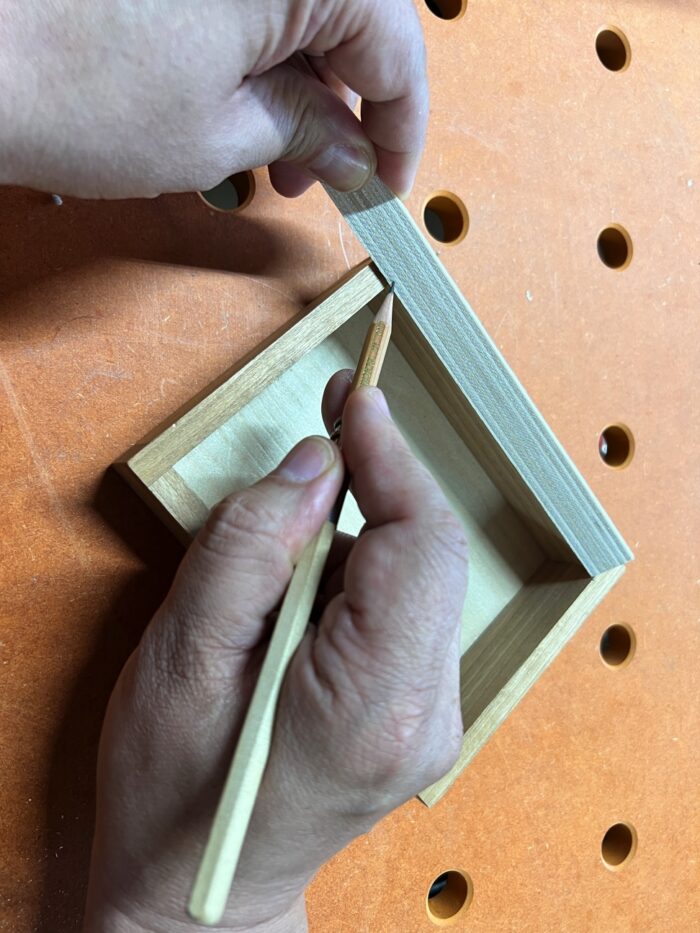

The better way to measure the size for the lid is to use a thin offcut of wood to mark the inside of the box. This guarantees that the size will be correct and you have eliminated the need for numbers and math. Take that stick to whatever tool you need to use to set power-tool fences or to strike lines in the case of hand-tool woodworking. If you’re making something that you build multiples of, you can save these referential measurements in the form of jigs or story sticks.

There are plenty of ways to have things go pear-shaped while building a wooden object. Eliminating math or number transcription errors goes a long way toward reducing those frustrations so you can focus on your techniques and skill as a woodworker. As for deciding between metric and imperial, ultimately that’s up to you and what works better for you. But I recommend ditching either system as early in the process as you can. You’ll have more accuracy in the end.

|

Vic Tesolin weighs in on the metric debateThe argument that “it’s just as easy” to work in fractional inches over metric is ludicrous |

|

Thinking of going metric?Guy Dunlap is experimenting with the metric system, but like many before him, he’s discovering that it might be all or nothing. |

|

Measuring precisionVic Tesolin relies on three main tools for measuring: a measuring tape, a rule, and a trusted frame of reference. |

Fine Woodworking Recommended Products

Veritas Micro-Adjust Wheel Marking Gauge

Lie-Nielsen No. 102 Low Angle Block Plane

Veritas Wheel Marking Gauge

Comments

It's easy to use a ruler or ruler to measure things badly. On the other hand, some tooling (e.g. router bits and drill bits) can have very accurate measurements built in, so using them in an equally accurate jig (e.g. a router & fence with a micrometer adjuster or drill press & adjustable-fenced table) can provide perfect accuracy.

But otherwise, ditching the measurers does indeed eliminate a big potential source of error. My own technique is to sneak up on the right size for a part, beginning with an over-measured piece then using a tool with a known measurable effect (a tablesaw micrometer on the fence or the thickness of a plane shaving) to pare the part down to the perfect fit.

Spot on. Use measurements to break down the wood and direct marking to make it all fit together. 👍

Log in or create an account to post a comment.

Sign up Log in