STL290: Lightning round with Vic and Ben

Vic and Ben answer eight listener questions, ranging from table saw throat plates to shiplap board spacingCalling all woodworking enthusiasts! Don’t miss the Texas Woodworking Festival, happening in Austin, Texas on August 26th and 27th. This event is a unique blend of an industry trade show, tool sale, educational seminar, and woodworking-themed festival.

Meet and connect with fellow woodworkers, lumber yards, woodworking organizations, content creators, furniture makers, and tool manufacturers. Enjoy live music, delicious food, and cold beer while exploring the latest tools, trends, and techniques in woodworking.

Get your tickets today at texaswoodworkingfestival.com and use the code “shoptalklive” to get 10% off your purchase.

Question 1:

From Len:

I have a question regarding rust and tools…I use jojoba oil on my planes and my chisels, but there are so many other steel surfaces…table saw top, band saw top clamps, etc. I try to be diligent about maintenance. I live in Washington State, on the wet side of the Cascades. My shop is in my garage, which is not heated. I have been wondering – would planes and chisels, etc fare better in a wall cabinet with doors that close? Would that help at all with rust prevention?

|

3 Methods For Removing RustRollie Johnson demonstrates how to remove rust from your tools and keep it at bay |

Question 2:

From Ian:

Do any of you use angled zero clearance inserts, perhaps like 30° or 45°? Any thoughts or recommendations on how to properly align for the critical blade raising to make a 30° or 45° insert? How would you suggest a safer way to make the inserts? Or is it worth doing at all?

|

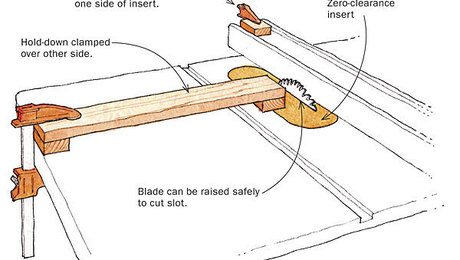

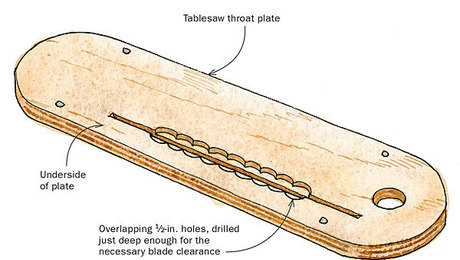

Slot a Zero-Clearance Insert SafelyHere’s how to safely cut a blade slot in a new zero-clearance table saw insert. |

|

Clearance For Installing a Table Saw Throat PlateIf you install a blank insert in your tablesaw’s blade opening, and bring the spinning blade up through it (making sure to hold down the insert in the process), you’ll create a zero-clearance slot that will prevent splintering on the bottom side of cuts. |

Question 3:

From Scott:

Seems every time I try to dimension a board to the thickness or try and take a cup out of a board, one end ends up thicker than the other. It is mostly the end I start my plane on that is narrower.

Question 4:

From Jim:

I’m building a small cabinet, approximately 2’ x 2’ x 2’ out of ¾” plywood with a closed back, also plywood. I plan on covering the outside with shop-made veneers. Do I need a balancing veneer on the inside or is the inherent stiffness of the plywood and of the box shape enough to counteract the changing tension of the shop-made veneer?

Question 5:

From Tony:

I’m a woodworking teacher in Australia and a long-time listener of the podcast. I was wondering what process would you recommend for setting hinges in boxes and cabinets. This is something I often spend way too much time trying to get right, and I was wondering if you have any great tips or advice to make the process easier.

|

Webinar: No-stress hinge and lockset installationJoin FWW editor and creative director Mike Pekovich for a webinar on installing hinges and locksets. |

Question 6:

From Buzz:

Putting shiplap boards in the back of a cabinet is a common practice, usually with a .125” gap between the boards and an over/underlap of .25”. How do you calculate the final width of the boards so that they fill the space accurately while maintaining the specs similar to the ones listed above?

|

Making a shiplapped backMike Pekovich shares a few tips for adding this simple and stylish feature to your furniture. |

Question 7:

From Ken:

What are your opinions on sophisticated electronics like brushless DC motor drives in the shop?

Question 8:

From Ken:

I saw the new FWW shop, it looks great!! I had one question for the podcast. I noticed you guys went with a hollow chisel mortiser. I’m curious if you guys considered a PantoRouter instead of the mortiser. I know Mike likes square holes in most of his work, which I do as well. But the cost for the panto router is about the same as the mortiser and I would like to get your take on which one is more versatile for a home shop. I could see the mortiser winning at speed and ease of use. I could see the PantoRouter winning when it comes to complicated angles.

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Dave Richard’s SketchUp course lays it out simply.

Always enjoy the videos, and yes, do not start an urgent project with an urgent need. But I bought the HF benchtop hollow chisel mortiser, honed the bits, bought a x-y vise and did the inverse hack, and it works fine. I am a hobby woodworker and have used on walnut, white oak, maple, and locust with no issues.

I live in Central FL and a method that works for me to keep rust at bay is I keep my planes, chisels, etc. in tupperware bins with a chunk of camphor. Once a quarter I'll go through and replace the chunks of camphor. For my planner, joiner, or other equipment that I don't use regularly, I'll drape an old sheet over the piece with a chunk of camphor under it and secure the drape with bungees or something similar.

Log in or create an account to post a comment.

Sign up Log in