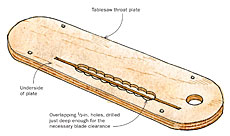

Clearance For Installing a Table Saw Throat Plate

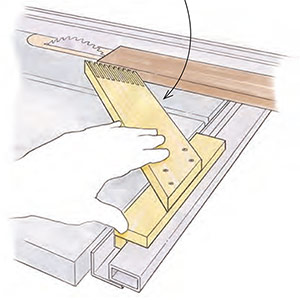

If you install a blank insert in your tablesaw’s blade opening, and bring the spinning blade up through it (making sure to hold down the insert in the process), you’ll create a zero-clearance slot that will prevent splintering on the bottom side of cuts. However, on some tablesaws, a standard 10-in. blade can’t be lowered enough to clear the bottom of a blank insert. To create the small bit of additional clearance needed, without weakening the plate, I drill a series of overlapping counterbores, using a 1⁄2-in.-dia. Forstner bit. This is easier than setting up a router cut, and better than ripping a shallow slot down the entire plate.

John Cuismano, Lansdale, PA

Comments

Just throw a 7 1/4" circular saw blade on and raise it up so it just punches through the throat plate. Reinstall your 10" and drop the plate over the blade. First time you use it, slide the fence over to hold down the plate then raise the blade to get your zero clearance.

Maybe use two 7-1/4" blades if they are typical kerf blades.

But I think the tip will work out to be faster. I like it.

Log in or create an account to post a comment.

Sign up Log in