Workshop tip: Simple wood block makes it easier to flatten backs of blades

This simple fix reduces wear and tear on your hands when you have a lot of blades to flatten.

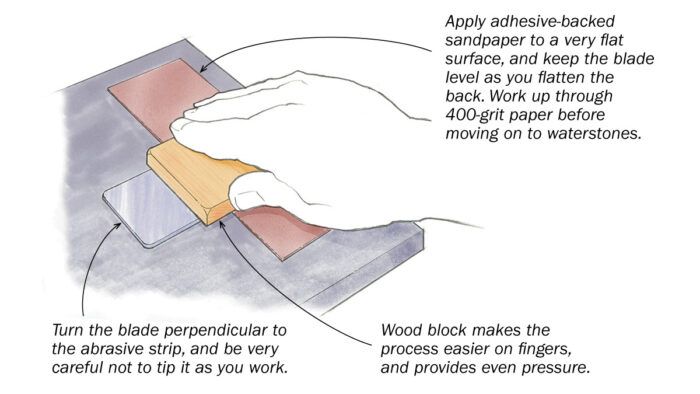

For many years I’ve really enjoyed tuning up vintage tools—mainly handplanes and chisels. Recently I was flattening and polishing the back of a new blade for a low-angle jack plane I’m restoring (a Stanley No. 62). I do this on a flat granite slab, using adhesive-backed sandpaper, and following up on waterstones.

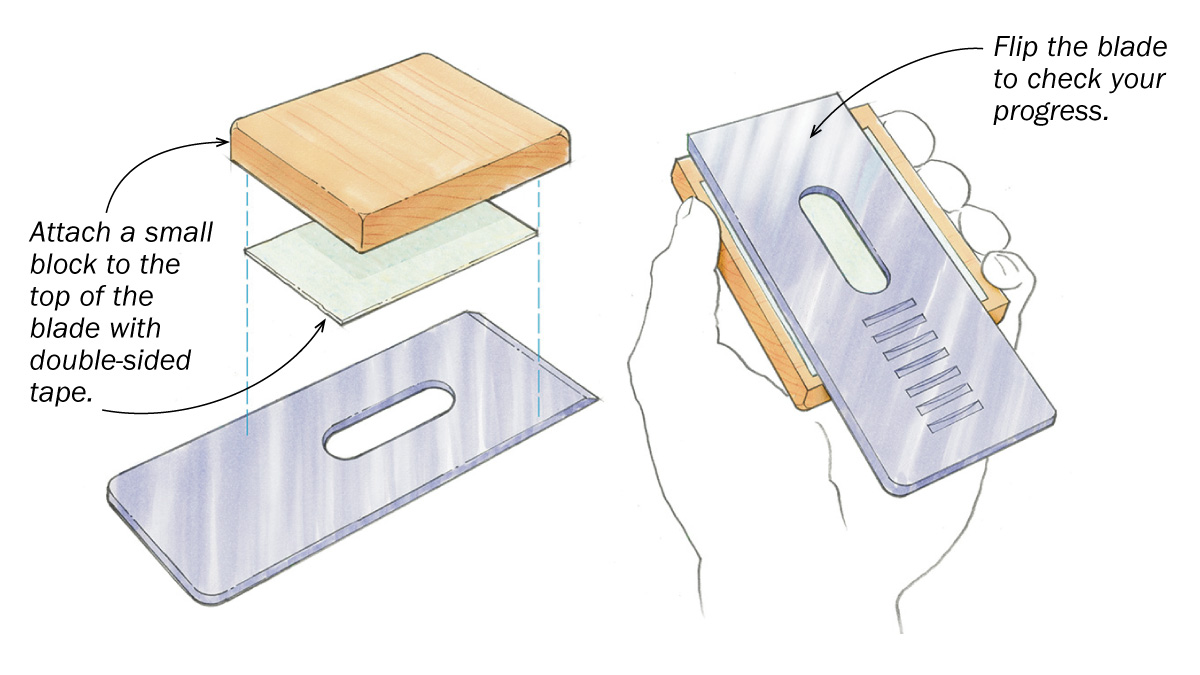

As usual during the initial flattening, which takes quite a while in some cases, my fingers got really sore. This time I even got a blister. I thought I’d better lay off the blade-lapping for a few days, and then I got the simple idea of attaching a small block of wood to the top of the blade to help me control the process. I attached the block with double-sided tape, went back to work, and the result was excellent! The blade honed much faster because I could apply even more downward pressure without a limited grip. The pressure was also more even and easier to control.

I wish I had thought of this years ago. It would have saved so much effort, and made tuning up all those chisels and plane blades far more enjoyable.

—EVAN MILLER, Sequim, Wash.

Illustrations by Dan Thornton

From Fine Woodworking issue #291

Fine Woodworking Recommended Products

Norton Water Stones

Wen Diamond Grinding Wheel

Log in or create an account to post a comment.

Sign up Log in