Make your own tools

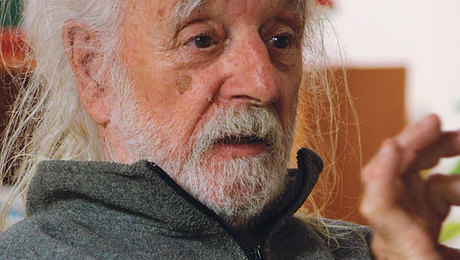

Vic Tesolin thinks that there is something remarkable about using a tool that you have made with your own hands to practice your craft.

I began my woodworking education at Rosewood Studio in Perth, Ontario, and was immediately immersed in everything there was to learn. Early into my time there we had a week where the focus was on making hand tools, and we started with planes. I started by making a jointer with a 1-1/4-in. blade designed specifically for truing up edges and removing the milling marks left by a power jointer. I went on to make a smoother with a 50° bed for dealing with more cantankerous grain and light figure. I also made another block-plane-sized smoother to prep the surfaces for eight-sided, tapered legs I made for a hall table. I finished off the week making a violin knife for getting into all those little nooks and crannies like dovetail sockets, and making a fishtail chisel from an old file to get into half-blind dovetail corners.

Big deal, you may say, you made some tools. Well, it is a big deal because each one of those tools was designed with a specific task in mind. Take the jointer, for example. It was tiny when compared to a traditional jointing plane. Only 15 in. long with a relatively narrow blade, but there was magic in that plane. It was lightweight, which made it easy to balance and maneuver on an edge of a board, but the real bonus to this plane was the mouth location. The blade was located 5/9 from the back of the plane, putting it just ahead of the center line. This layout made it extremely easy to not taper the edge by mistake. There was a lot of sole on the board, both at the beginning and the end of the stroke, all but eliminating those dreaded slopes at the front and rear of a jointed edge.

Shop Tour: Vic Tesolin

Check out Vic’s old shop and what he includes

in his “Minimalist” setup.

When you are working with lumber that is milled on machines, how often does a woodworker need to have the benefits of a full jointer with a 2-1/4-in. blade and a 22-in. sole? That’s just one example of how handmade tools can be real assets in the shop because they can be made to suit a specific task.

There is something remarkable about using a tool that you have made with your own hands to practice your craft. Handmade tools are built for you and come to the hand nicely. They are often made from wood, so there is a warmth about them, and there can be an overwhelming sense of pride when you work with them. I’ve made many of my own tools and have also had other craftsmen make tools for me that are just as special. My blacksmith Nick Verbree at oldsoldiertoolworks.com has made everything from hammers to dividers for me and I treasure each and every one of his tools.

So, head into the shop and start making your own tools. Don’t worry about finding resources, as there are many books and articles on the subject. The metal bits are the relatively expensive part of making tools, but about $50 for a plane blade and a chunk of hardwood is not what I would consider prohibitive. You’ll end up with tools that are built to suit your needs and the way you work. Making woodworking tools is not as difficult as you would think and the satisfaction in building them is off the charts.

In order to understand, you must do. – Vic

|

|

|

|

|

Fine Woodworking Recommended Products

Starrett 4" Double Square

Lie-Nielsen No. 102 Low Angle Block Plane

Veritas Wheel Marking Gauge

Log in or create an account to post a comment.

Sign up Log in