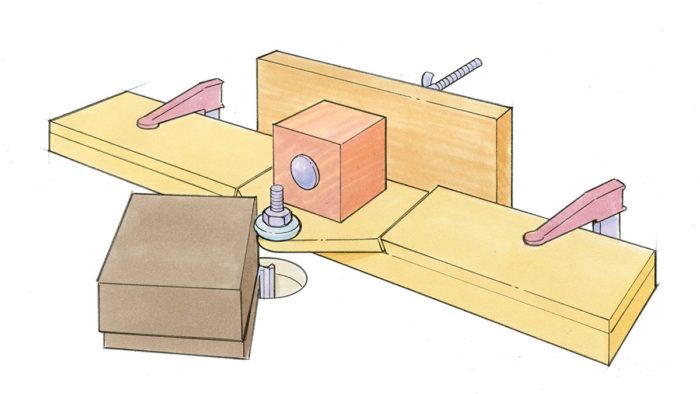

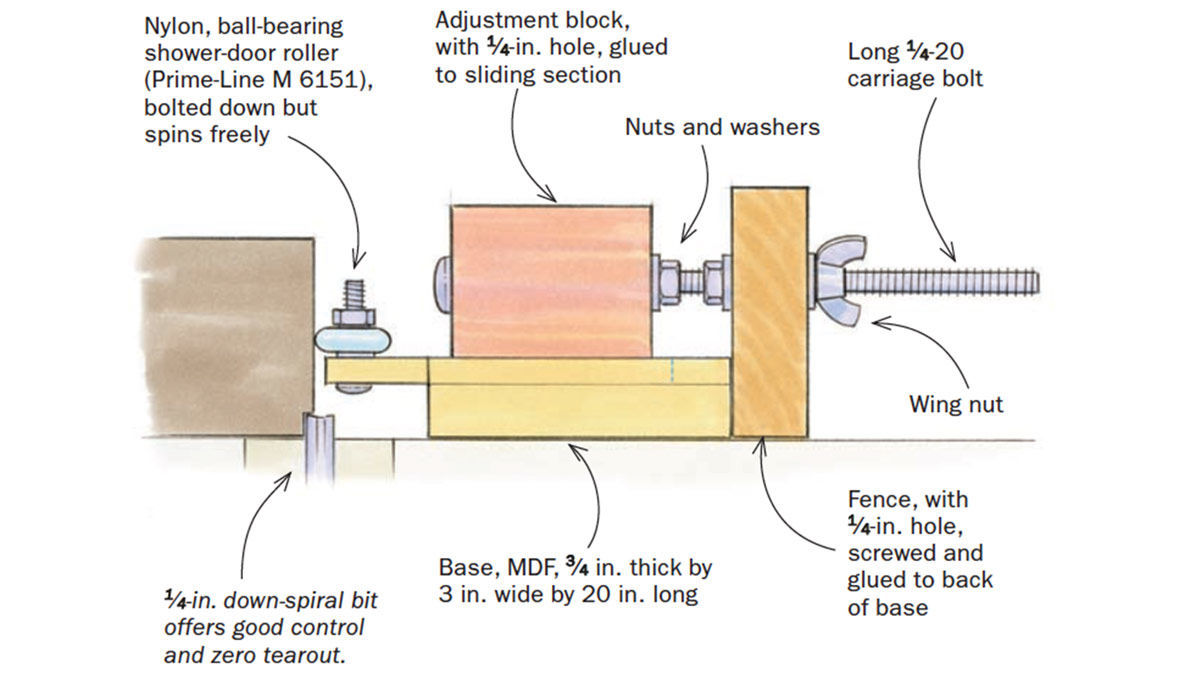

I created this jig to rout ledges for edge-banding (called “binding”) on the curved sides of a ukulele, but it will cut perfect rabbets for banding or inlay on all sorts of projects such as boxes, table aprons, and more. The key is the guide roller, which follows any surface, curved or straight, producing a perfect rabbet of uniform depth. Its big advantage over rabbeting bits is fine adjustment, down to a few thousandths of an inch. Setup is simple. After setting the height of the router bit—a 1⁄4-in.-dia. down-spiral bit works best—to the desired height of the rabbet, clamp the base to the router table with the center of the roller in line with the center of the bit. This doesn’t have to be exact. Now adjust the roller so the cutting depth is close to what you want. Try putting a block of wood against the bit, and then adjusting the bearing until your banding or inlay just fits between the block and the bearing. Make a test pass on some scrap, and fine-tune accordingly.

—Kirk Hopkins, Brashear, Texas

Drawings: Dan Thornton

From Fine Woodworking #274

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Grizzly G0495X Industrial Helical Cutterhead 8-in. Jointer

Veritas Precision Square

Comments

Hi Kirk,

I am building an artistic (non=functional) guitar/harp/piano about 3 feet tall. I wanted to band the edges of some of the curved surfaces and found that all of the rabbit bearing sets had a minimum setting of 1/8". That brought up the problem of bending 1/8" banding on tight curves. I saw your article and found myself saying "that's perfect." Thank you! Bill Raymond, Phoenix, AZ

Log in or create an account to post a comment.

Sign up Log in