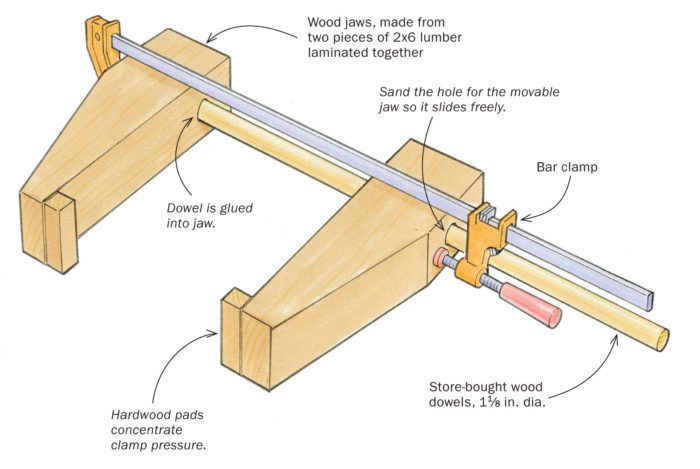

When working on a staircase, I needed a way to reach past a banister and apply clamp pressure. So I devised these jaw extenders for my F-style bar clamps. I later realized they would work for almost any job where I wanted to extend the clamp’s reach. A hole could be drilled through both jaws if you wanted to use a pipe clamp.

I made the wood jaws a bit beefy for the job at hand, but they could be sized in all sorts of ways. I used construction lumber and bought a big dowel. Both jaws are drilled for the dowel, and the fixed jaw is glued in place on one end. Another option is to use a length of 2×2 lumber instead of the dowel, dadoing each half of each jaw to create a square hole. I added small pads to the jaws to concentrate the clamp pressure.

—Roger Kaldahl, Eugene, Ore.

Drawings by Dan Thorton

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Trusty-Cook Dead-Blow Hammers

Comments

Great tip!

Isn't it strange that those old Pony Clamps can have their versatility improved upon????? Mine are 50 years old and I still prefer them over some of my newer ones that just hang on the wall...

Time to go to what my friend used to call, "Homeowner's Nightmare" for some 2x6's, dowels and a 1"x3" (to rip the 3" dim. in half lengthwise) of hardwood.

Log in or create an account to post a comment.

Sign up Log in