I recently invented a jig that makes great through-dovetails on the bandsaw—both pins and tails. It cuts the cheeks and also lets you remove some of the waste, leaving just a bit of chisel work. You need only a moderate skill level to use the jig but the results are super: pins as narrow as you like and a level of precision that is difficult for some of us to produce with hand tools alone.

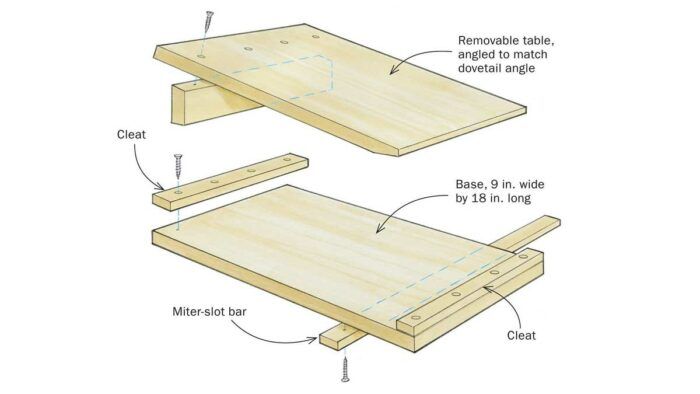

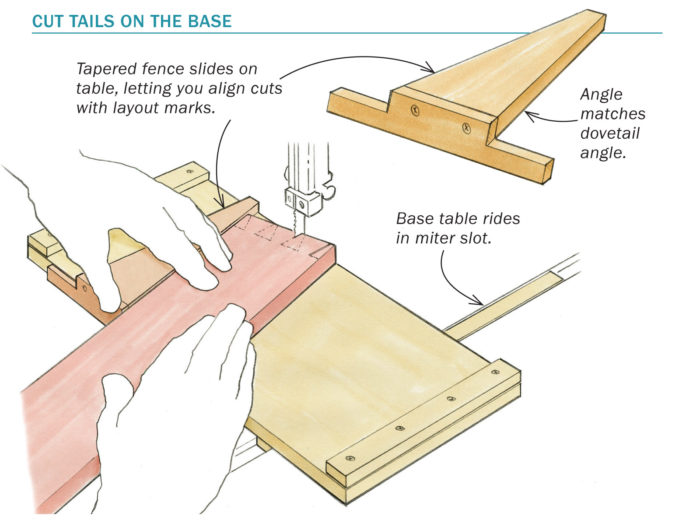

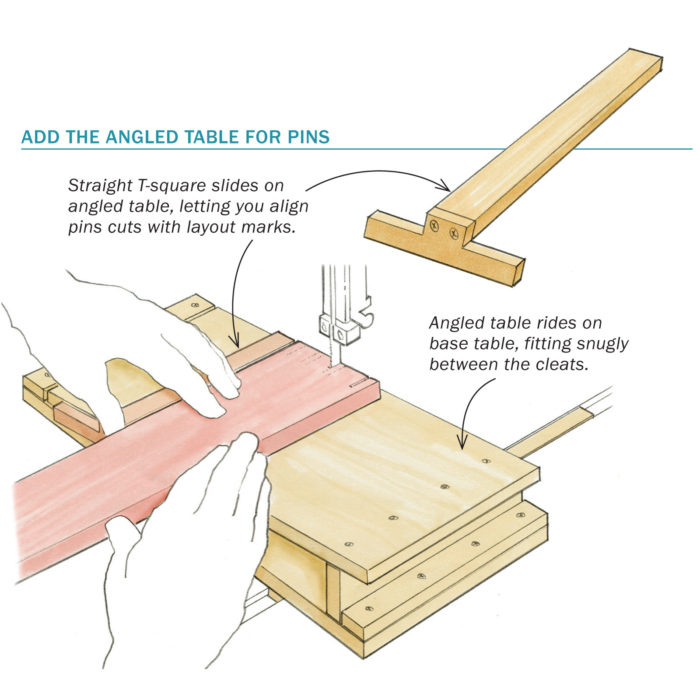

The base of the jig is a sliding table with a wood bar that fits in the miter slot on your bandsaw table. The tails are cut on that table with a small tapered fence holding the workpiece at the correct angle. For the pins, a sloped table fits between two cleats on the flat one, and a T-square holds the workpiece in position. Whether you want to cut pins or tails first, you’ll need to lay those out clearly, and transfer the layout precisely from pins to tails or vice-versa. With just a little practice, you can cut the second half of the joint for a very precise fit with the first half, with no additional fitting needed.

—Dan Sweeny, Westlake, Ohio

Fine Woodworking Recommended Products

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Suizan Japanese Pull Saw

Veritas Standard Wheel Marking Gauge

Comments

This is a great idea...I’m halfway through making this jig and can’t wait to try it out. Thanks for sharing!

I love dovetails, so I'm going to make a jig and try it out. Thanks for posting this technique.

Good idea, but I would prefer some way of fixing the sliding fence. Any ideas anyone?

In reply to JoeS01, a simple modification could give you the fixed sliding fence. Add a piece of T-track to the back of the bed and use a Bristol lever or a cam clamp with a T-bolt to lock the fence in place. something like this: https://flic.kr/p/Mhw8jb

There's a British fellow who has a different design. He sells the plans for it on his Bandsaw Jigs and Advanced Techniques DVD. See: https://tinyurl.com/ycqufl83

Link doesn't work

Another approach for the sliding fence would be to use 400 grit sandpaper on the inside faces to grip the surface without marking the jig up to much. That way it’s easy to move for each cut but still should stay firm. I’m building the 3D Bookshelves in December using this jig so I’ll update with results.

I may be overthinking this but when you out the angled bed on for the pins, how high do i make the board go for the angle?

Nebraska, typically that's a 10 degree angle.

I use a bandsaw for dovetails too, but I freehand them and it seems to work.

One trick I use for the sides of tails and pins is self-adhesive sandpaper on a steel rule. Hold it flat up against a tail with a bump on the side and just a couple of strokes will make it perfect (about 150 grit).

Log in or create an account to post a comment.

Sign up Log in