Quick-change router collet (aka Quick-Change Chuck)

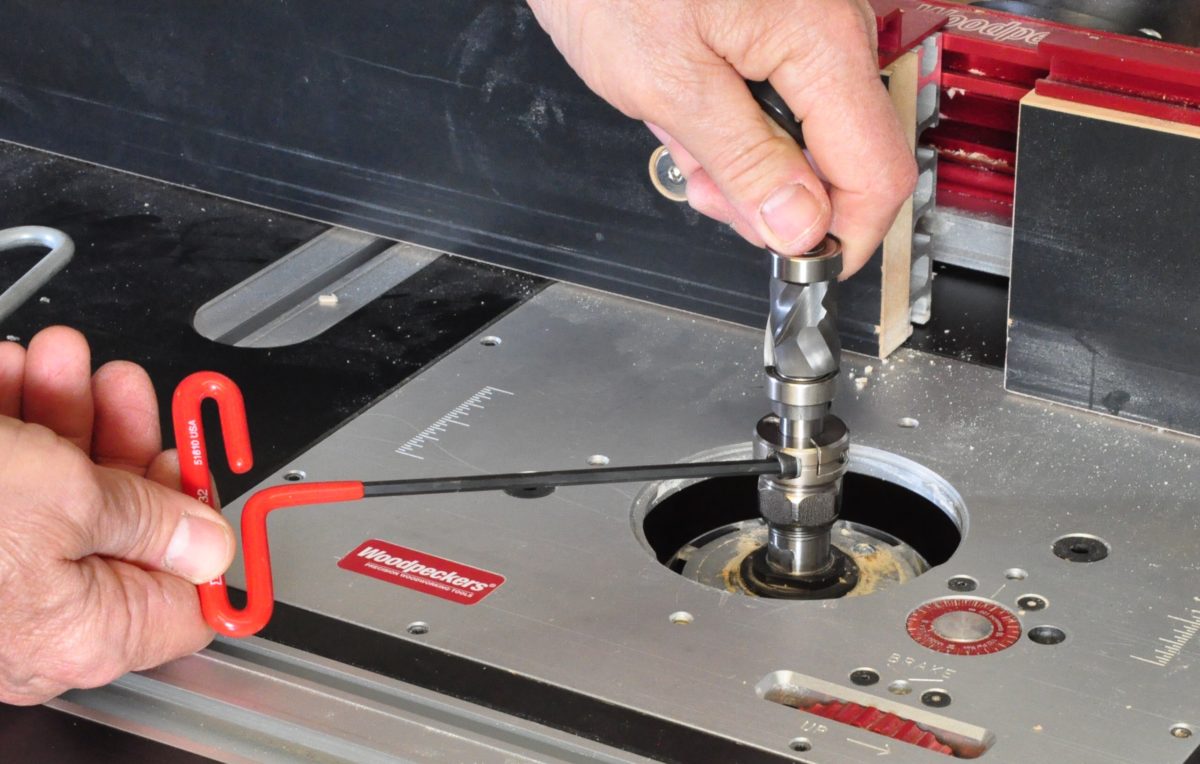

It doesn’t take much muscle to use this router collet

I hate dealing with stubborn router collets. I can’t count the number of times my collet wrenches have gone flying, or pinched my hands, while I’m trying to loosen a hard-to-reach collet, and owning more than one brand of router means the right wrenches are always in the wrong drawer. Spindle locks are supposed to be a big help, but they can add their own hassles when the lock plunger is buried under a router-table plate or router lift housing. Curses!

A few years ago I ran across a new type of router collet and it revolutionized my router routine. No longer do I need a pile of wrenches for all my different routers, and gone are the struggles with changing bits. One 5/32-in. Allen wrench is all I need. What a relief! And if a Bondhus-type ball-end wrench is used you can even loosen the collet when it’s slightly below table level.

Here’s what makes the new collet tick. Typical collets have a cone-shaped bit holder with slits in the cone that allow it to contract around the bit shank as the collet nut pushes the cone into its socket. The problem with this arrangement is that if the bit is bottomed out in the collet socket, the bit holder has to slide down the shank of the bit as it tightens. This can scar the shank, jam the bit in the holder, or worse, not tighten completely, allowing the bit to slip, wrecking the project as the bit moves out of the collet. We’ve all experienced a bit dropping (or raising in a router table application) and it’s beyond frustrating.

Adding to bit change frustrations with a standard collet is that the collet nut, once loosened, needs to be run up the threaded collet shaft until it pulls the cone out of the receiver, releasing the bit. Older-style collets don’t have a cone that is fastened to the collet nut, so a smart whack with a scrap of wood is usually necessary to release the bit. Tiresome. Not allowing the bit to bottom in the receiver can side-step some of this hassle, but in the heat of battle it’s often overlooked. Putting an 0-ring in the receiver can help; it gives the bit a little squish area, but it’s not a guarantee of a clean release.

The quick-release collet works by cinching the bit in place. The collet collar has a vertical slit that allows the collar to close around the bit shank and a horizontal slit allowing part of the collar to move. The collar becomes a small spring-loaded clamp. A bit can be pushed all the way to the bottom of the collet shaft without worry of jamming the bit—no slotted cone to seat, nothing pushing the bit

downward. A twist of an Allen wrench and the bit is securely locked into place. Releasing the bit is as simple: no jammed bit. A twist of the wrench and the bit easily slides out of the collet.

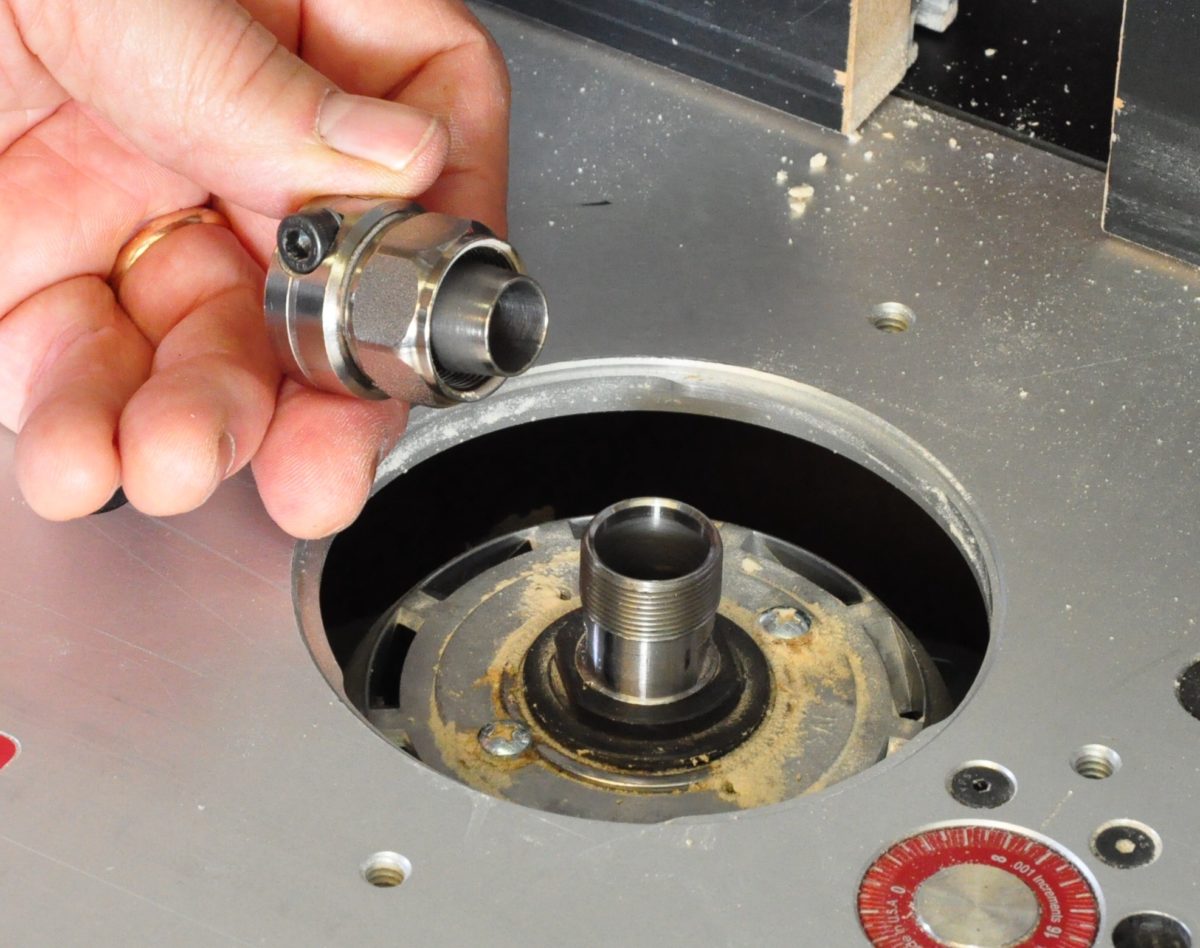

Installing a quick-release collet is a snap. It has a cone that fits in the receiver just like a typical collet. The cone doesn’t have slits because it doesn’t need to compress around a bit shank, it only needs to seat in the receiver. It’s a one-time installation and then you can throw those clumsy wrenches in a box and forget about them. Hallelujah!

On rare occasion, a little vibration of the collet/bit assembly may raise its nervous noggin. To eliminate the vibration simply mark the router motor shaft and the collet collar with an indelible marker, release the collet nut, move the collet assembly 90°, tighten the collet, install a bit (I use a piece of 1/2-in. drill rod—no cutters to worry about) and run it up to speed. If the vibration persists move the collet again. You will find a sweet spot where there is no vibration. Again, the vibration is the exception rather than the rule.

One small consideration: The quick-release chuck collar raises the collet height about 1/2 in. compared to the original chuck.

The chuck I use is the Muscle Chuck and there are different models that will match nearly any router.

If you use 1/4-in.-shank bits you will need to purchase a reducer, as all Muscle Chuck collets are 1/2 in. The reducer is designed specifically for the Muscle Chuck, a standard 1/4-in. reducer won’t work well as they tend to get locked in making it difficult to remove them.

Fine Woodworking Recommended Products

Makita SP6000J1 Track Saw

Festool Rotex FEQ-Plus Random Orbital Sander

Bosch 12V Trim Router

Comments

Does anyone use shapers anymore? It seems like having a solid spindle and nut is more capable... and it gets the motor and adjustments out where they should be...

73 Ely

Am I missing something? Whose opinion is this? Who wrote it?

Oops, forgot to put Rollie as the author. Fixed.

Ouch! The above link has Muscle Chuck for my Hitachi at $77 and the 1/4" adapter is another $35. I won't mention the T-handle hex key for another $12. Oh, I just did. And then shipping. I love the concept but I think I'll simply stand and curse if needed if I scrape my knuckles.

A really great convenience and helpful advice from a trusted author, especially on setup to eliminate vibrations. But I'd be hard pressed to shell out $100 for the hardware considering the frequency I change my router bits. But then again, maybe I'd be more inclined to use my router table if it became more convenient.

Ever wonder why propellers have a bearing right behind the mount? 1/2 rod might tell you about your router run out, but how about the run out with a 2 1/2" or higher and 1 1/2" plus in dia bit being extended further out beyond the router motor bearing? Router and almost all motors have short shafts for a reason. I have no problem with my 3 Rigid routers when any one of the is mounted in my home made table. I simply drilled a hole in the plate to line up with the spindle lock and use an ice pick to move the lock. Same ice pick I use instead of a clumsy push stick. Remember the further away from shaft support (bearing) a mass gets, the more any slight imbalance becomes magnified. I have a double bearing 2" pattern bit that I can not run at full speed in one of the routers.

I'll take the extra 15-20 seconds to change a bit.

Rollie has written about these before. I purchased one for my PC router in my router table AND one for my Bosch router in my CNC machine as I am constantly changing bits in the CNC. Mine were called the "Eliminator" and sold by Magnate on Amazon. Both work great, and have the collet reducer adaptors for 1/8", 1/4" and 3/8" bits. So far I have not experienced any vibration on either. Thanks Rollie!

Too bad the design of the chuck does not provide a balanced rotational inertia. That is why you mention vibration. Maybe I should design and patent a balanced chuck assembly.

mchris65

Log in or create an account to post a comment.

Sign up Log in