How to Cut Compound Angled Joinery

Demystify this seemingly complex woodworking joint with a simple set-up block

Although most woodworking joints are constructed at 90-degrees, there are times when design trumps everything and seemingly complex mathematics comes into play. Compound angles are a perfect example of this. Angled sides are used in all types of woodworking—think cradles and serving trays. The outward-sloping sides of these projects require cutting compound angled joints that can leave most woodworkers scratching their heads.

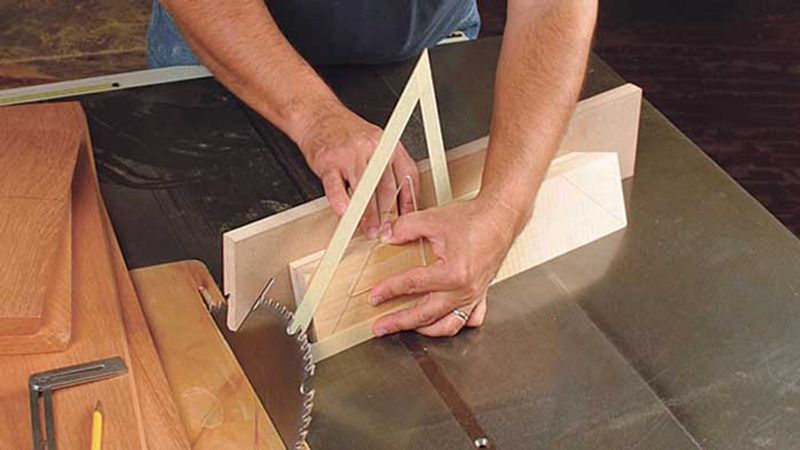

A compound angle occurs at the intersection of two sloped sides. Butt joints, miters, and even dovetails can be fit together in this manner. North Bennett Street School instructor Steve Brown’s simple set-up block takes math out of the equation and makes set-up quick and easy.

In this short video, Fine Woodworking senior editor Matt Kenney demonstrates how to make the set-up block and put it to use, as he cuts compound angled butt and miter joints.

See more on Compound Angles in FineWoodworking.com:

- Careful tenon layout is the key to cutting and mastering this intimidating joint

- Build a Stool with compound angles

- Compound angles without the math

- How to cut dovetails with compound angles

- Compound angles with the drill press

Comments

Great tips and it really does work! Can you continue this project with hints for clamping the compound miter joint and how to position/hold the tray to cut splines into the miter joints? Thanks.

I would also like more details on finishing this tray! Thanks!

See Fine Woodworking #158

This is a great technique, just not applicable to my European-style, sliding-table saw. I can't tilt the blade to the left nor can I cut safely on the right side of the blade.

I think there must be a solution using my compound-angle drop saw.

Will have a go.

The approach described in this video and in the FWW article word just fine but about a year ago I ran into a situation that baffled me for days. The described approach runs into a major snag when the slope angle on adjoining pieces are not the same. My specific project was making a child's cradle where the slope on the sides was 10 degrees while the slope on the toe end was 20 degrees. This was the cradle that Bill Pavlick built at the 200 Williamsburg conference. Would love to find an easy set up block method for unequal angle situations.

Maybe it's me but this seems to be a very confusing method. I'm an P.Eng. and learned how to do this in school. (The course was Descriptive Geometry.) No math involved.--Simply draw auxiliary views from the set of plans to get the true angles, true lengths and true shapes. A proper set of plans should include any necessary auxiliary views.

If you've got plans with only three views (top, side and front), that is probably fine for 90 degree case goods. If you have a project with compound angles like that butler's tray or the Williamsburg cradle with sloped sides and ends (like I have sitting upstairs), a proper set of plans absolutely must include auxiliary views.

These plans sound like more work than the tray.

Or, just use a compound sliding miter saw and make all the end cuts, and depending on the size of the saw, some of rips. This was a good idea if you have only a table saw to use and that seems seldom the case in most shops.

I have 3 compound sliding miter saws. None of them could ever be as accurate as what Matt shows. Not even the Kapex. And ripping on the miter saw is the worst idea in the history of power tools.

when I cut the blanks at 10 deg and then try to set the angle of the blade for mitres, it seems like my sawblade needs to go way further than 45 deg, which mine cannot do. What am I missing?

Very interesting. I'll have a shot at it. The one addition I'd like to see is adding splines to increase the strength.

I have tried to wrap my head around why you need to bevel the ends of the boards when making a butt joint. I tried these instructions for a 4-degree slope, using the setup block as described, and my saw ended up exactly at 90 degrees and the piece came together fine. Geometrically I just don't see why the cross cuts should not be at 90 degrees across the thickness as for any right-angle butt joint.

Log in or create an account to post a comment.

Sign up Log in