Synopsis: You can cut the most accurate joinery in the world, but if your glue-up is not done correctly, you’ve missed the boat. The secret is clamping cauls, sized and applied correctly so that you get the right amount of glue in the right places with the correct amount of clamping pressure. This Fundamentals shows how to make and use cauls for edge-gluing flat tabletops, applying edge-banding, bringing bookshelves all the way into their dadoes, clamping dovetail joints, and ensuring tight mortise-and-tenon joints.

We woodworkers spend a lot of time cutting accurate joinery. Yet even the most accurately cut joint won’t be perfect if you glue it together incorrectly. Not only must you put the right amount of glue in the right places, but you also need to do the same with the clamping pressure. Some joints, such as dovetails, need pressure only in isolated spots, while others, such as thin edge-banding, need even pressure over the whole area. The answer is not fancier clamps or specialized jigs; it is shopmade clamping cauls. Quick to make and easy to use, cauls not only pull a joint tight and keep it at the correct angle, but they also protect the workpiece from direct contact with the clamp jaws.

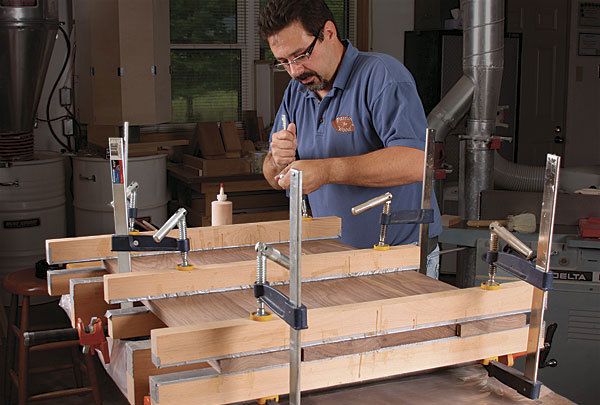

Flat tabletops start with cauls

Let’s start with the simplest cauls. When edge-gluing boards to make a solid-wood panel such as a tabletop, I use hardwood cauls about 1 in. thick by 2 in. wide by up to 30 in. long. I use them in pairs to sandwich the boards together and keep them flush while other clamps apply the main pressure to the boards’ edges.

Some woodworkers recommend putting a slight convex curve on the clamping faces of the cauls. For this job, I’ve never found it necessary. After all, no great force is being applied; you are only using the cauls to hold the boards flat, not bring them together. However, for panels wider than about 30 in., cauls are less effective. Splines, biscuits, or dowels will work better to align these boards, although they are more time-consuming.

Cover the cauls’ clamping surfaces with packing or duct tape to keep them from getting glued to the panel as squeeze-out oozes from the joints. Use a pair of cauls at each end of the panel, but if the panel is more than about 2 ft. long, use a third set of cauls in the center.

For the cauls at either end, have the clamps come in from the ends of the panel to get even pressure across all the joints. For the center pair of cauls, the clamps have to come in from the edges of the panel.

From Fine Woodworking #218

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Estwing Dead-Blow Mallet

Bessey EKH Trigger Clamps

Log in or create an account to post a comment.

Sign up Log in