Easy-Mount Featherboard for Table Saws

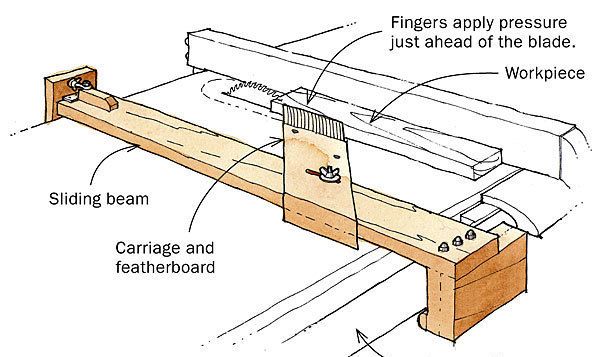

A featherboard can make for safer and more accurate tablesaw ripping and grooving. But most featherboard designs seem like too much trouble to set up and adjust, and those that clamp to the miter-gauge slot can’t be used with wide stock. This design, sized to fit my saw table and fence rail, sets up quickly and works with narrow and wide stock.

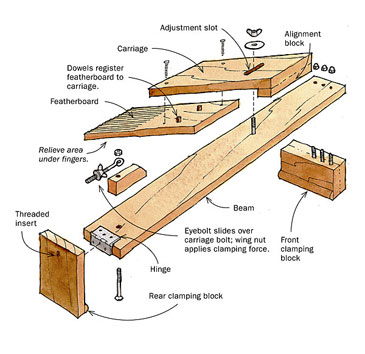

All of the wooden parts were cut from a maple 1×4, and the metal parts are common hardware-store stock. The featherboard and carriage both are mitered 45° on each end. I glued an alignment block on the back end of the carriage to register the featherboard parallel to the sawblade.

Before cutting the fingers on the featherboard, I made a single, light pass partway through the jointer on the underside so the fingers don’t drag on the tablesaw deck. Rather than gluing the featherboard to the carriage, I pinned it with wooden dowels and a couple of screws so that I can replace it.

To use the fixture, set the saw’s rip fence to the desired ripping width, put the stock in place against it, slide the beam over, and lock down the rear clamping block by tightening the wing nut on the eyebolt. Adjust the carriage so that the featherboard applies pressure just in front of the blade. You don’t want the featherboard pushing against the side of the blade, where it might pinch the workpiece and cause kickback.

This featherboard adds a measure of safety without being a hassle to set up. It saves me a lot of time because I don’t have to fiddle with miter-slot expanders or C-clamps.

Drawings by Jim Richey

Fine Woodworking Recommended Products

Hedgehog featherboards

Incra Miter 1000HD

Milescraft 4007 6in Bench Clamp

Comments

Not sure how this works, if the eyebolt is held from turning by the vertical carriage bolt and the eyebolt is threaded into the insert, it is not clear how the wingnut moves anything. I understand that moving the rear clamping block away from the carriage bolt would apply pressure on the bottom of the block, but it seems the wingnut only tightens what is already tight.

In reply to user-3020382, I think you're right. A clearance hole in the rear clamping block would make more sense. That would allow the clamping block to pivot on the hinge as the wing nut is tightened against it.

Log in or create an account to post a comment.

Sign up Log in