Tool Test: 6-in. Random-Orbit Sanders

Do these powerful machines have the finesse to finish the job?

Synopsis: What do 6-in. random-orbit sanders have over 5-in. models? For starters, 6-in. sanders have a larger sanding surface, more powerful motors, and many work in two modes. But are the extra weight and cost justified by greater productivity? Can you easily control the tool when it’s set on coarse mode, or will your crisp-edged workpiece end up looking like a piece of driftwood? How well do these tools deal with dust collection? Roland Johnson’s tests revealed a wide range of capacities and performances-far larger than the fairly homogeneous 5-in. sanders.

Models tested include the Bosch 1250DEVS, Bosch 3727DEVS, DeWalt DW443, Fein MSF 636-1, Festool ETS 150/3 EQ, Festool RO 150 FEQ, Makita BO6030, Makita BO6040, Metabo SXE450, Ridgid R2611.

From Fine Woodworking #202

One inch doesn’t seem like much, but when it comes to random-orbit sanders, it makes a large difference. For starters, the pad on a 5-in.- dia. sander is 19.6 sq. in., while that on a 6-in.-dia. model is 28.3 sq. in., giving you 44% more sanding surface. To drive this extra capacity, 6-in. sanders have more powerful motors, and many work in two modes—coarse and fine. The smaller sanders operate only in fine mode.

We wanted to find out what these larger sanders offer the typical furniture maker. Are the extra weight and cost justified by greater productivity? Can you easily control the tool when it’s set on coarse mode, or will your crisp-edged workpiece end up looking like a piece of driftwood? How well do these tools deal with dust collection? What we discovered was a wide range of capacities and performances—far larger than the fairly homogeneous 5-in.

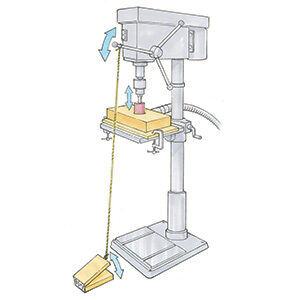

Let the sanding marathon begin: To test each sander’s stock-removal rate, we used the same method Andy Engel employed to test 5-in. random-orbit sanders (“Random-Orbit Palm Sanders,” FWW #185). We weighed an 8-in. by 24-in. cherry board on a scale accurate to 1 gram (28.35 grams = 1 oz.); then we sanded the board using a P100-grit hook-and-loop disk from Klingspor for exactly five minutes. Then we weighed the board again to see how much wood had been removed. We performed the test three times, each time with a fresh disk, and averaged the results.

Four machines have a fine setting only, one is exclusively coarse, and the remaining five were tested in both modes. All but one sander had variable speed control, but to maintain consistency, all the tests (see head-to-head results, pp. 66-67) were done with the sander at the maximum speed setting.

We also evaluated how effectively each machine collected dust, whether using an onboard system or hooked up to a vacuum. To test the former, we weighed the machine before and after each test, comparing the weight gain of the machine (and its dust cup/bag) to the weight loss of the board to calculate the percentage of dust that was collected. To see how well the sanders worked with a vacuum, we used a Festool vacuum with removable paper bags, weighing the bag before and after each test and comparing it to the change in the board’s weight to calculate the percentage of the dust collected.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Craftsman Random Orbit Sander

Festool Rotex FEQ-Plus Random Orbital Sander

Fein Turbo II HEPA Wet/Dry Dust Extractor

Log in or create an account to post a comment.

Sign up Log in