Question:

I would like to cut a 9-in.-wide octagon on the tablesaw. How can I do this safely?

Stewart Levine, via Knots online forum, None

Answer:

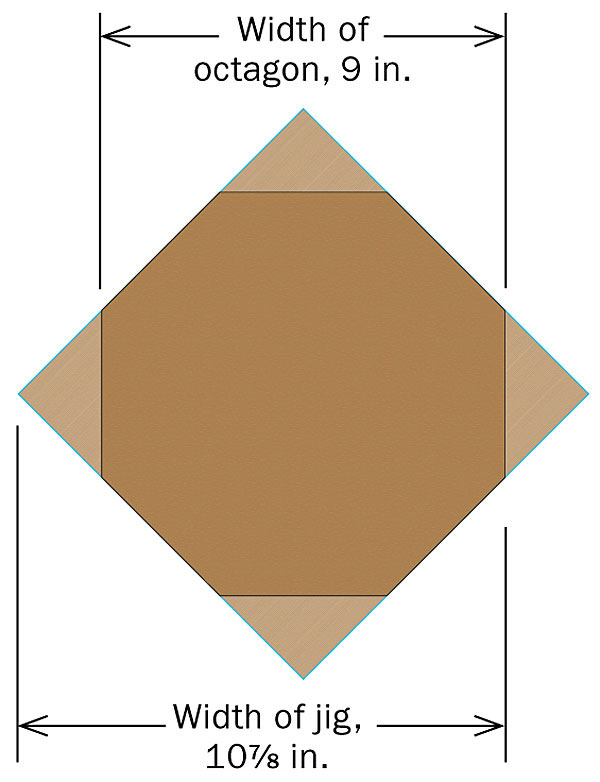

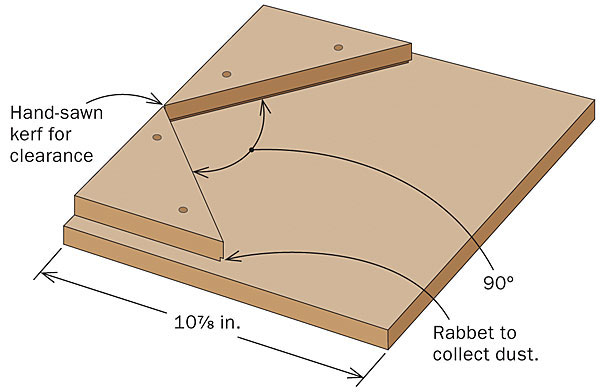

For a 9-in. octagon, start with a blank that is 9 in. square. For the jig, begin with a plywood base 3/4 in. thick by at least 9 in. long. To determine the width, multiply the side of a square by 1.41 (in this case, 9 × 1.41 = 12.69 in.). Subtract the 9-in. width from 12.69 in., and you get 3.69 in. This is the sum of two opposite corners of the square blank that will be removed to create an octagon. Divide 3.69 by 2 to get 1.84. Add 1.84 to 9, and the result is 10.84 or a hair less than 10-7/8 in. This is the width of the jig and the distance from the fence to the sawblade.

Cut a pair of 45° triangles. Attach them to the jig as shown in the drawing. Use a backsaw to open a sawkerf gap where the two points touch. Place the blank in the jig, and cut off a corner of the workpiece. Turn the workpiece 90º and repeat three times to leave a perfect octagon.

|

|

Fine Woodworking Recommended Products

Grizzly G0495X Industrial Helical Cutterhead 8-in. Jointer

Ridgid R4331 Planer

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in