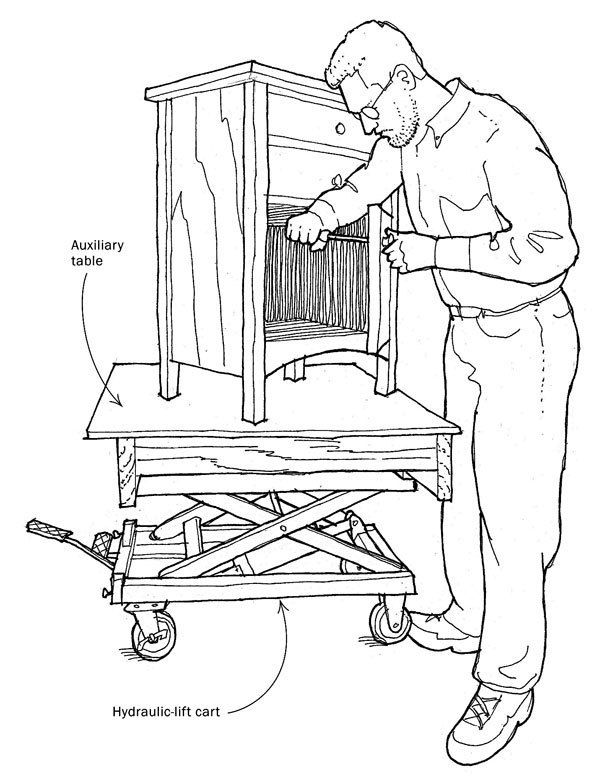

Variable-Height Worktable

Like many woodworkers, I used an assortment of less-than-ideal methods — tables, crates, sawhorses, and knockdown boxes, among others — to raise workpieces to comfortable working heights. Even then, I often found that I needed the workpiece at several other heights as construction progressed. For example, I might start out working on the base, then the drawers, and finally the top. For each of these steps, the ideal working height is different. I wanted a means of easily moving a workpiece up or down. Looking through an industrial-supply catalog, I spotted just what I was looking for — a hydraulic-lift cart. The cart uses a hydraulic cylinder, a foot pedal, and a scissor-type lifting mechanism to move a platform up and down parallel to the floor. The cart I purchased came with a 20-in. by 32-in. steel table and four 5-in.-dia. casters.

I built an auxiliary table from framing lumber and plywood. It increases the area of the top and elevates it about 8 in. Now the cart adjusts from 19 in. to 38 in. If needed, I add a blanket or scrap of carpet to serve as a protective pad under the work.

The cart makes work go easier and faster in a number of ways. In addition to the up-and-down movement, I can roll my work around the shop when repeated cutting and fitting are required or when I want to take advantage of the best light. I’ve also used it to transport heavy materials from one end of the shop to the other. Hydraulic-lift carts are available from companies like Amazon.com or Grainger (www.grainger.com) and start at about $150. The lifting capacity on my cart is 600 lb. It weighs about 130 lb.

Drawing: Jim Richey

Drawings by Jim Richey

Fine Woodworking Recommended Products

Incra Miter 1000HD

Hedgehog featherboards

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in