Chucking Bowl Blanks

It seems to me, in reading past methods on woodturning, that many turners must be spending more time fiddling with faceplates and attaching the work to the lathe than actually turning. I’d rather spend my time turning, so I devised this quick procedure that takes me from a blank to a finished 10-in. dia. bowl with 1/8-in. thick walls in 30 minutes.

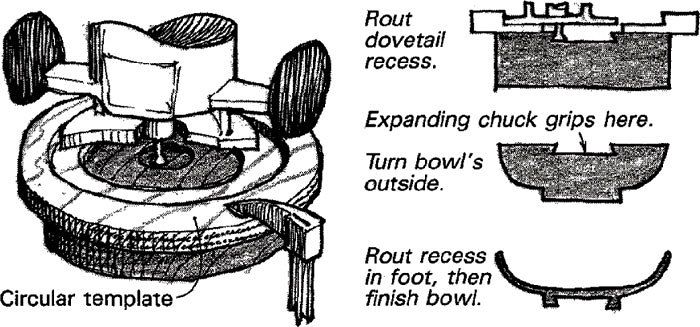

The key to the method is a 6-in-l Universal Chuck, which has an expanding collet that locks into a dovetail recess in the workpiece. First I cut a recess in the top of the blank, using a router with a dovetail bit and the circular template shown in the sketch. The router rides around inside the shoulder on the template to produce a recess to fit the chuck.

With the circular blank mounted on the chuck, I turn the bowl’s outside profile. At this point you can turn a chuck recess in the bottom of the bowl if you choose, but I find it easier and faster to remove the bowl and cut the new recess with the router. It’s important to center the bowl’s foot in the template before cutting the recess, otherwise the bowl will wobble on the lathe. If you turn the foot to fit the center hole in the template, this won’t be a problem.

Now I return the bowl to the lathe and complete the inside. If desired, you can part off the bowl above the foot to eliminate all signs of the attachment method.

F.H. Crews, High Point, N.C.

Fine Woodworking Magazine, February 1984 No. 50

Fine Woodworking Recommended Products

Double Sided Tape

CrushGrind Pepper Mill Mechanism

Incra Miter 1000HD

Log in or create an account to post a comment.

Sign up Log in