18th-Century Six-Board Chest

Copying an original is an excellent way to hone your hand-tool skills

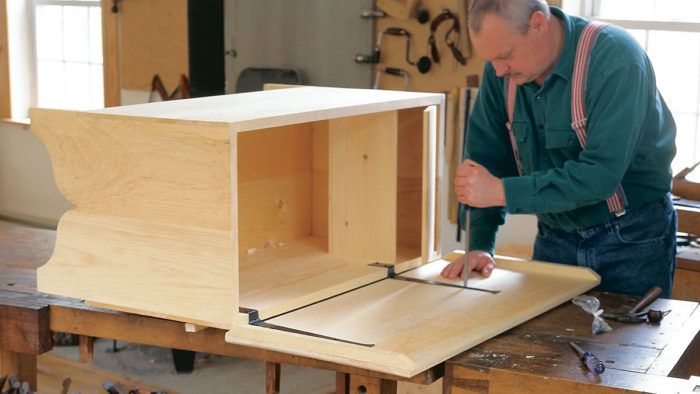

Synopsis: This project is a good one to hone your woodworking skills, Michael Dunbar says, either by machine or by hand. He offers tips on handsawing and jointer planing to get better results with less effort. He explains how to surface the panels and cut them square, and how to cut boot-jack ends and the stop joint, how to cut the rabbets and dadoes, make the till and assemble it without glue, and how to make and fit the lid. Dunbar demonstrates how to edge-glue panels, and a project plan includes details on till construction and thumbnail molding on the chest lid, bottom corners, back panels, and boot-jack ends.

This copy of a ca. 1800 blanket chest—also known as a six-board chest—is an ideal project for honing your woodworking skills. While the chest can be made by machine, its various parts are made equally well (and about as fast) by hand, It was fun to spend a few afternoons making something by hand. It reinforced for me how delightful the shop can be when the only noise is the whisk of sharp tools. I rediscovered how pleasant woodworking is without hearing, eye and lung protection. When a storm knocked out the power one afternoon, I was able to keep working. It was delightful—just me, the wood, the tools and the sunlight.

At first glance the chest appears to be little more than a nailed box. As you make the project, you’ll begin to respect simple joinery that requires mostly rabbets and dadoes. You’ll begin to realize how much today’s woodworking has developed construction into a design element. The original chest from which this one was copied White pine chest made the old way. Using sharp hand tools, the author made a blanket chest in a few afternoons. The till—a box within the box—is used to hold small items. has been in continuous use for nearly 200 years and is still solid and very much intact. Its survival is not unique. The chest seems to violate an important woodworking principle, in that the grain of the ends and sides is arranged in opposite directions. One would expect this to cause the front or back boards to split. However, that did not happen to the original example or to the untold numbers of other chests like it. Unlike glue, the nailing allows enough movement to compensate.

The original chest is generally referred to as a blanket chest, underscoring its purpose—to store folded items made of cloth. However, this was also a utilitarian piece of furniture usually kept in a bedroom against the wall or at the end of a bed. An average house would have several such chests.

The original piece’s everyday function dictated a couple of construction choices for the cabinetmaker. Time-consuming joinery, like dovetails, was replaced with equally strong rabbeted joints. The original was made in New England, where white pine is still sold everywhere. Had the cabinetmaker been working in another region, he might have used yellow poplar. I used 5/4 clear white pine. The original box was made when a 1-in. board was a full inch thick. I felt the proportions of the original were important to the chest’s overall appearance, which is why I chose 5/4 stock. The exception is the chest’s bottom panel, which I made from -in.-thick #2 pine.

From Fine Woodworking #134

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Stanley Powerlock 16-ft. tape measure

Comments

How do you download the free plans? All I get is a bogus browser extension.

The view PDF button at the bottom of the page should do it.

Log in or create an account to post a comment.

Sign up Log in