Synopsis: Strother Purdy of Fine Woodworking explains how to read grain, which can tell you a lot about a board – where its strengths and weaknesses are, what direction it will move most, and which are the best ways to cut a particular board. He shows how to read grain orientation, and he spells out right and wrong ways to cut against the grain. He talks about how to use a board’s strength to benefit your project, and he offers advice on joining boards with different grain.

As one of our contributing editors is fond of saying, a board’s grain is a bit like a cat’s fur. If you brush the cat’s fur in the wrong direction, you tend to make the cat hiss. Brush it in the right direction, and the cat purrs. Working wood with the grain will yield smooth boards. Cutting it against the grain will give you endless grief, Grain, however, is a bit harder to read than fur. But being able to read wood grain is an important part of working the material successfully. Grain can tell you quite a bit about a board. It can tell you where a board’s strengths and weaknesses are and the direction the wood will move most. Grain patterns will also recommend the best ways to cut a particular board.

GRAIN PATTERNS DESCRIBE THE STRUCTURE OF WOOD

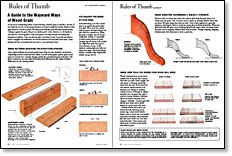

Lines of grain delineate the annual growth rings of the tree and, therefore, its structure. Depending on how a board has been milled, you will see flat grain, quarter grain or end grain on a board’s face. Usually, though, lumber isn’t cut with end grain on the face. The grain’s orientation not only makes the lumber look different but also makes it behave differently.

GRAIN DIRECTION DETERMINES A BOARD’S STRENGTH

If you’ve tried, you know that wood is far easier to split along the grain than it is to break across the grain. This is because wood is made up of tough cellulose fibers that are about 100 times longer than they are wide. They’re held together by a glue-like substance called lignin, which is much less strong than the fibers themselves. When you split wood with the grain, you’re breaking lignin bonds (easy); when you break across the grain, you’re snapping cellulose fibers (much harder). Though tempting, designing furniture parts with short grain is never a good idea.

From Fine Woodworking #130

For the full article, download the PDF below:

Fine Woodworking Recommended Products

AnchorSeal Log and Lumber End-Grain Sealer

DeWalt 735X Planer

Ridgid R4331 Planer

Log in or create an account to post a comment.

Sign up Log in