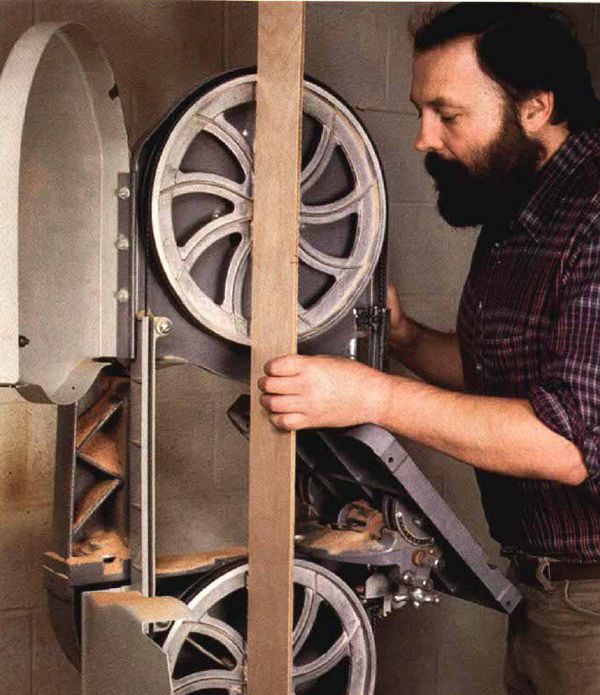

Adjusting Bandsaw Wheels

Small alignment changes improve performance

Synopsis: For top bandsaw performance, you must fine-tune the saw, paying special attention to wheel alignment. It takes no special tools, gadgets or miracle blades, just a little time and attention and a shim or two. In this article, Mark Duginske explains how to achieve good alignment, the variables of poor tracking, how tension affects tracking, how to check and shift the wheel, and a few final tricks, such as rounding the blade’s back corners.

The bandsaw can be one of the most useful tools in the shop: It can resaw thick stock or slice off thin veneer and cut curves, circles, tenons, dovetails and more. But don’t expect it to do all these jobs well straight from the factory. For top performance, you must fine-tune the saw, paying special attention to wheel alignment. This takes no special tools, gadgets or miracle blades, just a little time and attention, and a shim or two.

In the course of my travels in the past 10 years, teaching classes and giving seminars on woodworking tools and techniques, I’ve adjusted at least 100 different bandsaws, Most of these were poorly tuned, and many were miserably out of adjustment. Unfortunately, when a bandsaw doesn’t work correctly, people tend to blame the machine, the blade or themselves rather than alignment or any other adjustment. Some workers seem almost afraid to mess with the machine, but the method I’ll describe here is simple and virtually foolproof, if you follow the steps properly. But before getting into the “how to,” I’ll explain a bit about the dynamics of a bandsaw and why misalignment can be such a complex problem.

Good alignment-For any blade to cut accurately, the wheels of the bandsaw must drive it smoothly and continuously. Proper wheel alignment is essential for this to happen, just as correct wheel alignment is necessary for a car to travel in a straight line without excessive vibration. For top performance, the wheels must line up with each other in three ways, as shown in the drawing above. The wheels must align in the vertical axis, be in the same plane and be parallel to each other. When the wheels are aligned all three ways, I refer to them as being “coplanar.” With poor wheel alignment, the blade can hop around on the wheel, yielding an erratic cut. These undesireable movements will shorten the life of the blade and the thrust bearing, as well as wear the guides unevenly.

Because bandsaw wheels have no rims, the only thing that holds the blade on the tire covering the wheel is proper tracking. To adjust the tracking, you must alter the angle of the bandsaw’s nondriven wheel while the blade is running. On most saws, this adjustment is made by screwing a knob in or out. This tilts the arbor supporting the top wheel, which in turn causes the blade to run or track on a different section of the tire. The goal is to keep the blade riding evenly on the wheel: A properly tracked blade will run without rubbing hard against the thrust bearing or coming off the wheel.

Blade tracking is also enhanced by the crowned wheels found on most small American and Taiwanese bandsaws, like the Delta, Sears and Grizzly.

From Fine Woodworking #75

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Makita LS1219L Miter Saw

Shop Fox W1826

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in