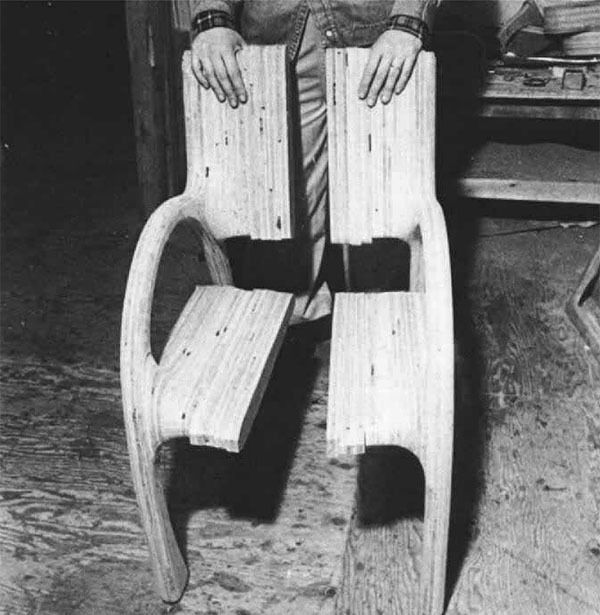

Synopsis: Ellen Swartz explains why working mostly with plywood appeals to her. It isn’t suitable for traditional joinery, though pinned finger joints work well, she says. Once her drawings are complete, she draws up the first slice. Cuts are made with a saber saw or bandsaw, and she assembles a slice from smaller pieces when needed. She uses a gouge and mallet for rough shaping, and an auto body grinder to sand them down. She says abrasive tools are better than sharp-edged ones because they cause less chip-out. The article also includes a brief history of plywood.

Making plywood furniture and understanding that process as a possible vehicle of social consciousness are primary concerns of mine. The material I use is secondary, although many people are struck by it first, foremost and finally. In 1970 I was searching for material to use in my simple shop and “found” plywood. It was easily available, inexpensive, strong when laminated, and could be worked with the basic tools I had. The more I used it, the more it appealed to me. I use it so there is very little waste (political appeal); it isn’t rare or precious so my prices can reflect that (social appeal); I can scrounge plywood at construction sites for smaller works (economic appeal); and the simple and direct methods of construction allow me to concentrate more on concepts than technique (personal appeal; i.e., knowing your strong points and limitations). All said, we seem suited for each other.

The technique of making plywood by fastening thin strips of wood together and alternating the direction of the grain to give greater strength has been known since the time of the ancient Egyptians. At the Step Pyramid at Saqqara (2700 B.C.), plywood was found in which six 1/4-inch layers with alternating grain directions were fastened with wooden pegs. However, it was the demand for plywood for building ships and planes for the First and Second World Wars that brought about the product we know today. Until that time, the impermanency of casein, animal and vegetable starch glues retarded the development of plywood. The improved casein glues of the 1920s and 30s were used in airplane construction, but repeated cycles of wetting and drying caused eventual deterioration. The development of resin glues in 1935 made available an adhesive which is waterproof and immune to bacterial attack. It is unaffected by wet-dry cycles or intense heat and makes a permanent weld. In plywood glued with phenol resins, the glue lines are stronger than the wood. From an engineering standpoint, the advantages of plywood are impressive. It is extremely strong in comparison to its weight. It is durable, and it is permanently cured so there is no checking or splitting as with solid wood.

There are many ways of putting plywood together to make furniture. For the past 40 years, molded plywood has been well developed by industrial furniture designers.

From Fine Woodworking #6

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid R4331 Planer

AnchorSeal Log and Lumber End-Grain Sealer

DeWalt 735X Planer

Log in or create an account to post a comment.

Sign up Log in