All About Lumber Storage

If there is a universal problem in the woodworking shop, it is lumber storage. To work efficiently, you need a good inventory of solid wood and sheet goods. Your inventory of solid wood and sheet goods needs to be stored compactly and efficiently but in a way that allows easy access to every board without having to move the whole stack. Although these attributes sound almost mutually exclusive, many woodworkers have devised storage systems that come close. In this article, we’ll discuss the most common solutions and link you to same additional tips and plans to build your own lumber storage.

The Basics:

• Storing solid wood: Horizontal racks keep lumber at the ready.

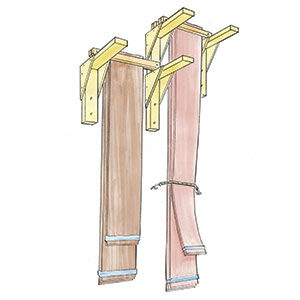

• Easy-access sheet goods: These heavy materials shouldn’t be hard to reach.

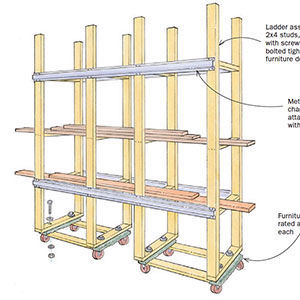

Storing solid wood

For solid wood, many woodworkers prefer solutions based on horizontal racks. The racks must be engineered to carry the cumulative weight of many pieces of lumber. Various solutions employ iron pipes as shelf standards or a heavy framework made from 2x4s or 2x6s. Virtually all storage racks utilize the inherent strength of the shop walls and the strength of wood under compression.

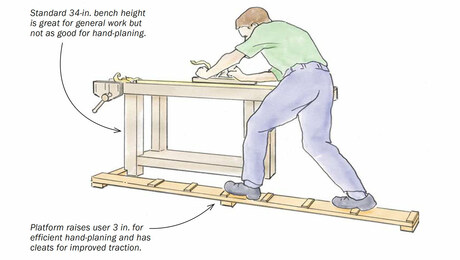

This inventive rack by Chris Gochnour lets you stack and saw lumber in the same spot.

Storing sheet goods

Sheet goods present another set of storage problems. If you just lean the sheet goods against the wall, the sheet you need will invariably be at the back of the stack. Most of the creative solutions to storing sheet goods I’ve seen through the years provide some way to partition the pieces or to flip through them easily to pick out the piece you need.

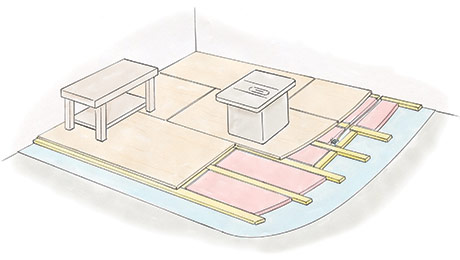

Some of us will have the opportunity at some stage of our woodworking odyssey to design and build a shop from the ground up, and the storage of lumber is, of course, an important element of shop design that must be considered. Solutions can range from shops designed around wood storage to rolling carts that carry lumber of all shapes and dimensions.

Log in or create an account to post a comment.

Sign up Log in