Curved drawer fronts: how to cut them to length and rout drawer bottom grooves

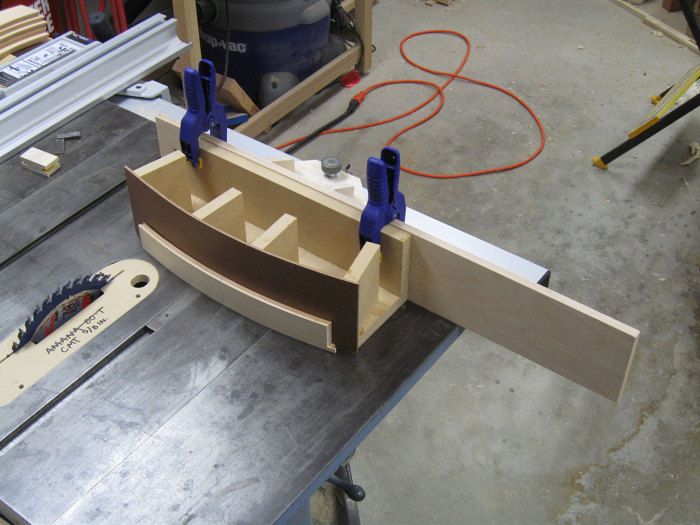

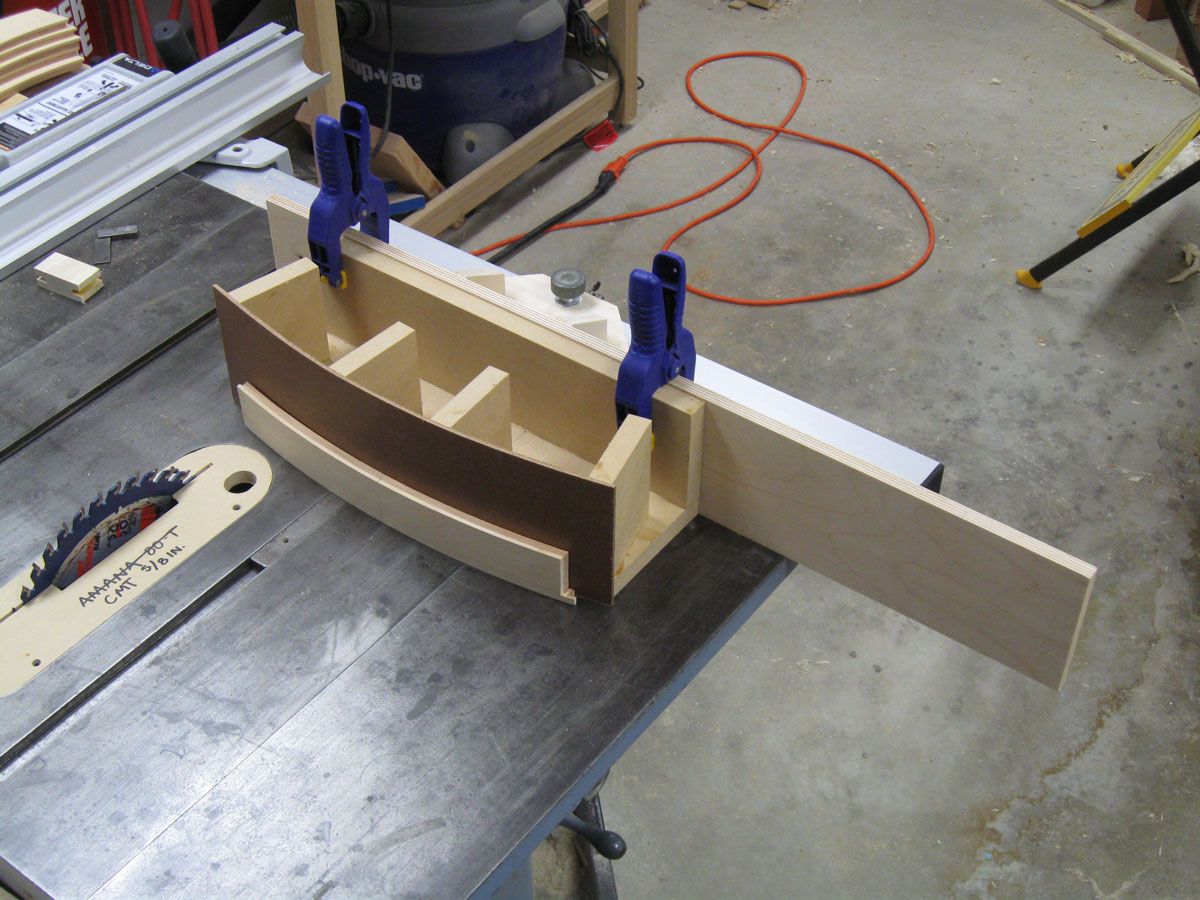

Solution, Part 2: I made a fence like the one I used at the router table for my miter gauge. It lets me orient the drawer front on edge and feed it directly into the blade. The blade intersects the front with an identical angle as the drawer sides.

I’m in the final stages of making a bow-front jewelry cabinet for my wife. All that’s left is to make the 17 little bow-front drawers for the interior of the cabinet! I’ve made enough drawers with curved fronts to know that they present two challenges. First, there is the problem of cutting them to length and getting the correct angle on the ends. Second, there’s the little issue of the groove for the drawer bottom. I’ve seen plenty of solutions for both problems, but none of them were easy and most involved cumbersome ways of measuring the angles and holding the drawers.

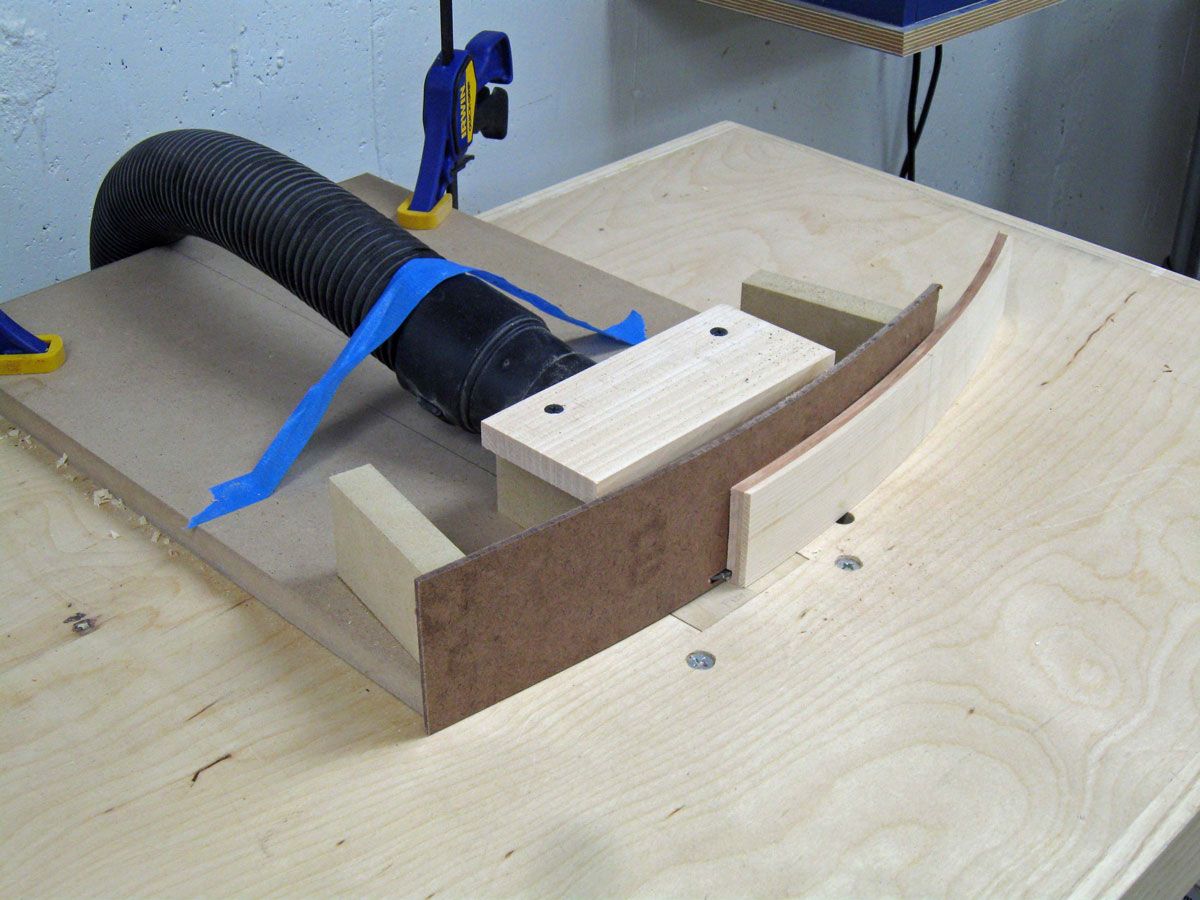

After thinking about the problems for some time, I finally hit upon a solution. First, I realized that I could make a curved fence for my router table and use a slot-cutting bit to make the drawer bottom groove. I experimented with solid fences made from MDF and it worked well, but I always hated the fact that the fences used up a lot of MDF and always required some real PITA work to make a pocket in the fence for the bit. So, then I had an idea. Make a curved base from a single layer of MDF and cut a notch for the bit at the bandsaw. Then glue some “fence posts” along the curved front and attach a hardboard fence face to the posts. Brilliant! (I wish I knew where the brilliance came from!) This type of fence works great. The grooves are cut to a consistent depth all the way around the concave face of the drawer fronts.

Of course, I was still struggling with how to cut the fronts to length. But then I realized that I could take a fence just like the one for the router table, attach it to my tablesaw’s miter gauge, put a drawer front on the fence and then feed it directly into the blade. The correct angle would be cut by default. Fantastic! A single fence solves both of my problems! I am, of course, very excited about this (and wish I could have more good ideas!).

Learn about the special fence for safely routing the drawer fronts in Part 2.

Comments

Great little tip! Thanks for sharing.

Good tip, I think?

If EVER a tip needed video or a LOT more photos, this would be the one!

How are the fences held together? How did you determine the correct curve and then get the hardboard to conform to it? Where exactly is the slot that was cut on the bandsaw? On the tablesaw, the picture looks like each cut would destroy your fence; how do prevent that? To get the length correct, how do you deal with the non-centered, non-symmetric curves of the drawers that do not span the entire width of the cabinet?

I think this one may need an article...

Matt's genious strikes again!

I love your solution. It shows real insight into the strengths and limitations of tools as well as the mechanics of jig construction.

A real triumph.

A far easier solution for the drawer bottom slots is to use a Box-Slotting Bit (http://www.leevalley.com/en/wood/page.aspx?p=47818&cat=1,46168,46176&ap=1). The bearing rides along any surface, curved or flat, and best of all, you can dry-fit your drawer or box with clamps, cut your bottom slot all the way around, and not have unsightly corner gaps. Slotting while dry-fit together also insures that the bottom slots line up perfectly.

jazzflute: I've got another blog coming to explain how I cut the drawer front blanks into small drawer fronts. I did use the same fence for my miter gauge.

msdr: I am aware of the bit from Lee Valley, but I don't think it's a better solution in this case. First, I don't fancy routing the a small drawer that's held together by a band clamp (these drawers have a curved front and traditional clamps wouldn't work to hold it together). And if I were to do the drawer front by itself, with no fence, then I'd need to balance a workpiece much taller than it is wide on the narrow edge--not a good idea. And it's really not difficult to get the grooves in the sides to line up with the one in the front.

Also, the fence has the added benefits of covering the majority of the bit during operation and dust collection.

Log in or create an account to post a comment.

Sign up Log in