Make Strong, Simple Joints with Dowels

Dowel joints offer a simple, strong way to make fine furniture and are often the best solution when other joints don’t work.

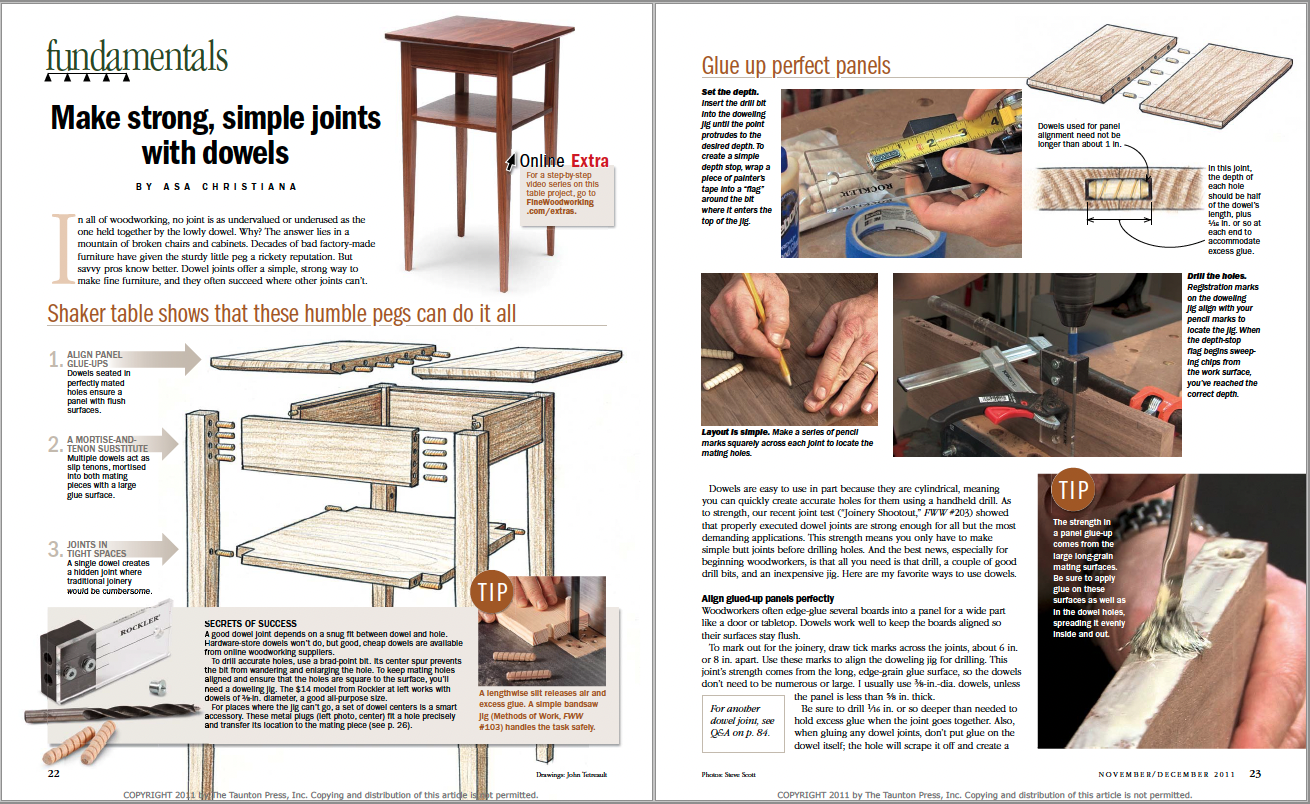

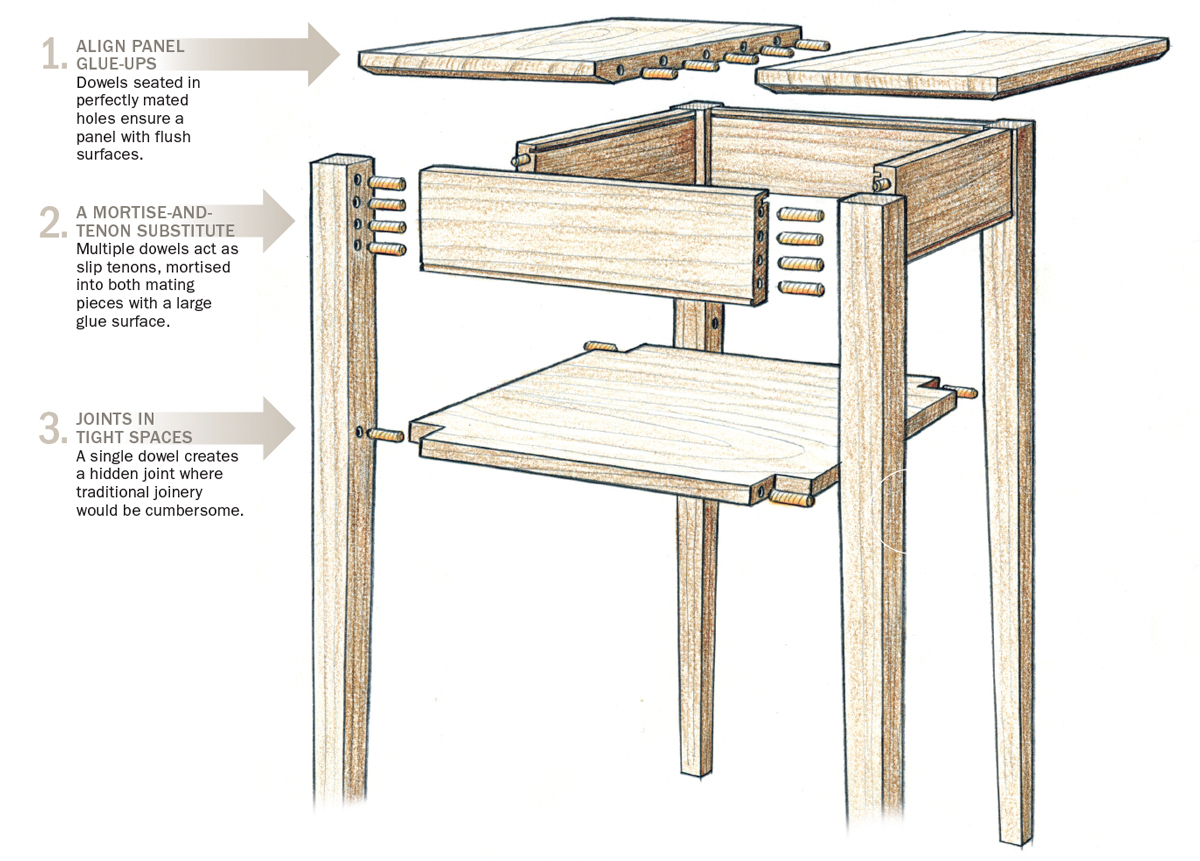

Synopsis: The lowly dowel joint may be the most undervalued, underused joint in woodworking. It owes that reputation to decades of bad, factory-made furniture. But done right, the dowel joint is a simple, strong way to make fine furniture, and often is the best solution when other joints don’t work. Use it to align panels, substitute for a mortise-and-tenon, and as a solution in tight spaces where traditional joinery would be cumbersome.

In all of woodworking, no joint is as undervalued or underused as the one held together by the lowly dowel. Why? The answer lies in a mountain of broken chairs and cabinets. Decades of bad factory-made furniture have given the sturdy little peg a rickety reputation. But savvy pros know better. Dowel joints offer a simple, strong way to make fine furniture, and they often succeed where other joints can’t.

Dowels are easy to use in part because they are cylindrical, meaning you can quickly create accurate holes for them using a handheld drill. As to strength, our recent joint test (“Joinery Shootout,” FWW #203) showed that properly executed dowel joints are strong enough for all but the most demanding applications. This strength means you only have to make simple butt joints before drilling holes. And the best news, especially for beginning woodworkers, is that all you need is that drill, a couple of good drill bits, and an inexpensive jig. Here are my favorite ways to use dowels.

Shaker table shows that these humble pegs can do it all |

Align glued-up panels perfectly

Woodworkers often edge-glue several boards into a panel for a wide part like a door or tabletop. Dowels work well to keep the boards aligned so their surfaces stay flush. To mark out for the joinery, draw tick marks across the joints, about 6 in. or 8 in. apart. Use these marks to align the doweling jig for drilling. This joint’s strength comes from the long, edge-grain glue surface, so the dowels don’t need to be numerous or large. I usually use 3⁄8-in.-dia. dowels, unless the panel is less than 5⁄8 in. thick. be sure to drill 1⁄16 in. or so deeper than needed to hold excess glue when the joint goes together. Also, when gluing any dowel joints, don’t put glue on the dowel itself; the hole will scrape it off and create a mess. Instead, put glue in each hole and spread it with a small brush or stick.

Build sturdy tables, doors, and cabinets

Almost any joint that calls for a mortise-and-tenon—table bases, door frames, face frames—is a candidate for dowel joinery. because this joint relies exclusively on the dowels for strength, you need longer dowels—and more of them. A good rule for dowel size here is one-half the thickness of the workpiece, with 3⁄4 in. or more extending into each hole. A 3⁄8-in.-dia., 2-in.-long dowel works great in most situations. To ensure that the holes in the mating pieces line up accurately, start with the jig referenced along a common edge. In this case, use the top edge of the rail and the top of the leg, which will be flush when the pieces are assembled. Also, don’t apply glue to the mating surfaces.

From Fine Woodworking #222

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Olfa Knife

Leigh D4R Pro

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Log in or create an account to post a comment.

Sign up Log in