Hey everyone, relatively inexperienced woodworker here. I’m looking for a reality check on a pedestal table design I’m about to build. I’m worried about stability, particularly the propensity to tip over or shear the top from the pedestal. The client is my gf’s mom, so if this goes wrong I look forward to hearing about it at every holiday for the rest of my life. Pics attached.

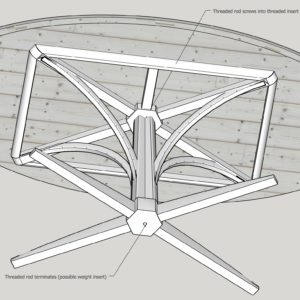

It’s all ash. The top is oval, 1 5/8″ thick, 6′ x 3′, made of dominoed 4-5″ wide boards with alternating ring orientation. The pedestal column consists of an X-shaped tapering column (5″ across at the base, 3.5″ at the top) sandwiched between two hexagonal pieces (bottom hexagon is 3.5″ thick, top is 1.5″ thick). I’m planning to run a threaded rod through the column to lock these parts together and screw the rod into a threaded insert on the underside of the table.

Also under the top is a substructure of 1.25″ thick ash (not quite an apron) that screw/dominos into the top along the long axis. Elsewhere, I’m planning to attach the substructure into the top using something that accomodates expansion. Hopefully this should be sufficient to keep the top from warping, which should be minimal anyway.

The feet are 20″ x 3″ x 1.5″ and are dominoed into the bottom hexagon. They extend the X shape of the central column — if they were on a clock face they would hit the 2, 4, 8, and 10 (60, 120, 240, and 300 degrees). I’m considering adding weight to the underside of the bottom hexagon but haven’t decided that one yet.

I really don’t want to make a table that tips over or falls apart if someone sneezes on it. Any advice would be greatly appreciated.

Replies

You might find this useful:

https://www.finewoodworking.com/2017/09/20/sketchup-tip-wheres-the-tipping-point

I don't think its going to tip over. I think the base is wide enough to support that. On the other hand, if someone leans on the outer edge of the table, it can put a lot of pressure on the joints for the very bottom feet. I would worry about racking in that case. Maybe add some triangulation support on the lower pedestal like you did in the upper part? Another design option is to make a trestle style table. You shouldn't have to worry about anything with that kind of table

Good point about the feet - someone else suggested using mortise and tenon instead of dominos to better tie the feet into the bottom of the pedestal.

I wish trestle was an option but the client rejected every trestle design I sent over. She wants the pedestal.

maybe something like this? Anyway a person might lean will be supported from top to bottom without adding a lot of pressure on one point.

Today’s glued are stronger than the wood being glued, so I wouldn’t worry about using tenons. When I designed/built an open 6 ft bookcase that had 50 joints I used slip tenons. It was so nice to build that I no longer use tenons except for through tenons.

This forum post is now archived. Commenting has been disabled