Workshop Tip: Turn a drafting square into a shop square

All you need is some gray primer and a plastic drafting square.

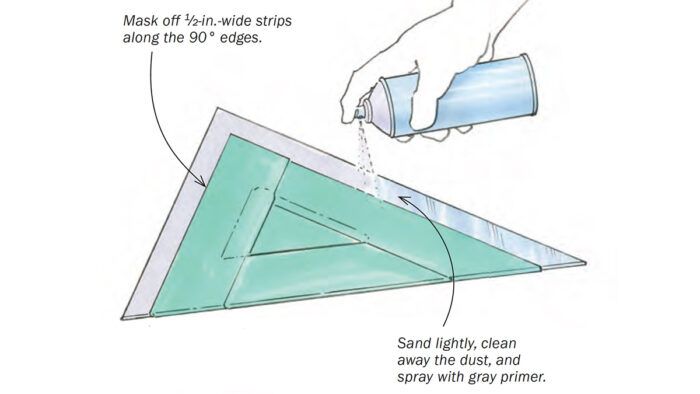

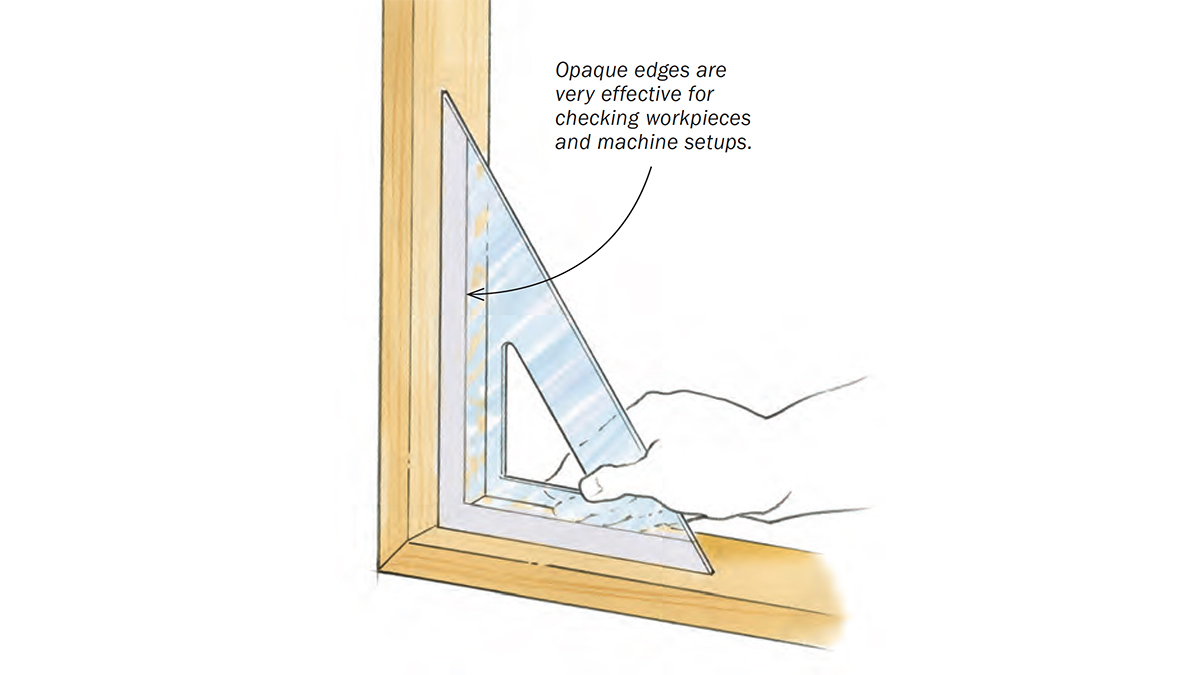

Not all shop squares are 100% accurate, but plastic drafting squares are. Being transparent, however, they make it tough to see gaps between the square and whatever you are checking. To make the two 90° sides more distinct, mask off 1/2-in.-wide strips at the edges, lightly sand the exposed plastic, clean off the dust with solvent, and spray with gray primer. After the paint dries, the edges will look like steel, turning an inexpensive craft-store square into a precise shop tool.

—DAVID GLEASON, Houston, Pa.

Illustrations by Dan Thornton

From Fine Woodworking issue #296

Fine Woodworking Recommended Products

Veritas Micro-Adjust Wheel Marking Gauge

Lie-Nielsen No. 102 Low Angle Block Plane

Tite-Mark Marking Gauge

Comments

I beg to differ on the drafting squares being 100% accurate. Some are but I did a fair amount of drafting in the 70's and 80's and found more than a couple that were not close enough to draw with. I bought an engineering squair from Taylor tool after Mike Pekovich mentioned a devider he bought from them. It's German made, guaranteed to be within a couple thousandths over 20 inches and way less money than the red aluminum squairs. I use it for machine tune ups and checking the and adjusting the squares I use every day. Otherwise it stays in a safe place, in the box it came in.

Most woodworkers know but for those who may not, squares are easy to check by laying it along a straight edge, drawing a line perpendicular to the straight edge then flipping the squair along the straight edge and checking the squair against the line.

Be safe, Have fun.

Agreed. I had been using a drafting triangle to set the blade angle on the table saw for 45deg. cuts, and couldn't figure out where my error was coming from until I checked the triangle against a machinists angle. The triangle was out by at lease a degree. It was a Staedtler - German made.

As for painting the edge - just run a sharpie along the edge - makes a perfect contrast - the KISS principle.

You can avoid the painting process if you use a drafting triangle with a "built in" metal edge. These triangles are designed so you can use an Exacto knife or similar for cutting or trimming without damaging the edge. Of course the triangle still functions as a drawing/drafting aid.

It's a bit difficult to see the edge in the photo but it's there.

Log in or create an account to post a comment.

Sign up Log in