The mighty mortise-and-tenon

Jon Binzen assembled a collection of articles on this powerful, protean joint.

For most anyone working solid wood—particularly if they’re building furniture—the mortise-and-tenon joint is essential. Learned early and used often, it’s a staple of the craft, and its virtues seem immutable: strength, simplicity, durability. Yet it’s also remarkably flexible and versatile, taking scores of shapes, sizes, and decorative flourishes. Many makers settle on one or two standard approaches to cutting mortises and tenons, but both halves of the joint can be produced in dozens of different ways with a wide variety of tools.

I’ve put together a collection of articles on this powerful, protean joint. Mario Rodriguez starts off with an anatomy of the joint and follows that with descriptions of 11 of the most common variations, while Contributing Editor Chris Becksvoort delivers a classic tutorial on creating quick, clean mortises using a drill press and a mortising chisel. Gary Rogowski’s article from issue 142 explores a dozen ways to make a tenon, including both machine and hand methods. Then machine maven Rollie Johnson addresses the stalwart hollow-chisel mortiser, explaining how to tune and use one.

Two longtime contributors write about vital variations on the standard mortise and tenon: Jim Richey, who edited and illustrated FWW’s Methods of Work column for 40 years, wrote and illustrated an article about cutting the wedged through-mortise and tenon; and Contributing Editor Steve Latta elucidates in his article the ins and outs of drawbored tenons.

For a dash of inspiration, I’ve included Hank Gilpin’s article presenting some of the many ways he spices up the mortise and tenon—the backbone of his furniture—through marvelous shaping and innovative deployment.

It’s been fun trawling through the archives to put this collection together, but painful having to leave out so many wonderful articles. I hope you enjoy putting the ones I’ve collected into practice. And take notes as you do—there’s always room for another interesting article on the mortise and tenon.

Mortise and Tenon Variations

By Mario Rodriguez

The mortise-and-tenon joint is one of the most dependable methods for joining wood parts of almost any size, configuration, and angle. I once restored an 18th-century timber-frame farmhouse and it stood perfectly plumb and strong after 200 years; it didn’t lean or creak one bit, all thanks to the mortise-and- tenon. If you’re making a piece of furniture or other project that requires unfailing strength, durability, integrity, and good looks, the reliable mortise-and-tenon is a great choice—but which to pick? There are many variations of this fundamental joint. You can keep it basic, or you can add flair to suit your design. I’ll take you through the basics of the mortise-and-tenon, including its parts and how to size the joint correctly for your projects. I’ll also show you a few fun variations— some of them don’t even need glue.

Cut a Mortise in Minutes by Christian Becksvoort

The time-honored practice of cutting mortises with a drill and chisel can be frustrating, because chiseling out the waste between drilled holes can easily go awry. Furniture maker Christian Becksvoort has refined the technique over the years to a four-step process that delivers clean, accurate mortises in just a few minutes. He begins with careful layout, then drills out the waste. Third—and this is key—he uses a mortising chisel and an unconventional technique to lever out most of the waste. And finally, he cleans up the mortise with a bench chisel. Simple, effective, and consistent.

Tenoning Strategies by Gary Rogowski

This article offers a taxonomy of tenons, detailing six variations of the ubiquitous joint, and details the wide range of methods available for cutting them. Rogowski covers cutting tenons with hand tools and follows up with an array of power-tool methods, including multiple techniques for the bandsaw, radial-arm saw, tablesaw, and router.

Master the Mortiser by Roland Johnson

Hollow-chisel mortisers are a godsend for woodworkers, easily cutting mortises of almost any length quickly and accurately; but they are among the most finicky of power tools. When not properly set up and used, this is a machine that can plague you with jammed chips, overheated bit and chisel tips, burnt workpieces, and broken parts. Once you learn the right way to set up your mortiser, however, you’ll find this aspect of joinery turns effortless. FWW contributing editor Roland Johnson shares his tips, starting with the proper way to sharpen and install the chisel and bit, and ending with advice on cutting expert mortises.

Through Mortise-and-Tenon Joinery by Jim Richey

It’s hard to hide mistakes in through-mortise-and-tenon joints. Their delightful signature—that the tenons show in these strong, attractive joints—is also their drawback. The fit of the tenons to the mortises is on full display. Longtime Methods of Work editor and artist Jim Richey uses a drill press for making his through-mortises, and he explains how to do so while avoiding tearout. He cuts the mortises first, then uses a shopmade saw to clean out the corners. He also explains how to lay out and cut the tenons, cut the wedges, and assemble everything.

Drawbored Tenons by Steve Latta

Drawboring a mortise-and-tenon joint means offsetting the hole in the tenon so that the pin pulls the parts together tightly—and permanently. If your tenon shoulders are square, your assembly will be, too. You’ll no longer need clamps, which can damage workpieces and pull them out of square. Your furniture parts will be square and will fit better. And your workflow will improve, because you will no longer have to wait for glue to dry. Just pin the joints and keep on moving.

Juice Up Your Joinery by Hank Gilpin

Hank Gilpin fell in love with the mortise-and-tenon more than 40 years ago, and he’s been playing with the joint ever since, finding ways to add strength and ramp up the visual impact. Here, he shows a variety of beefed-up joints, including multiple tenons for maximum strength and impact, shaped through-tenons to add zing, open mortises, wedged tenons, and the stylish tusk tenon.

Fine Woodworking Recommended Products

Leigh Super 18 Jig

Festool DF 500 Q-Set Domino Joiner

Veritas Standard Wheel Marking Gauge

Comments

Thank you for an interesting selection.

What is missing is a really good discourse on the physics/mechanics of the joint.

How long does a tenon NEED to be for instance? Clearly the tenon needs some length, otherwise it is a butt joint. Longer tenons will resist pulling better as they have more glue surface, but at some point this will exceed the strength of the wood and a longer tenon will add no more.

Longer tenons might be expected to resist racking better, but does the longer tenon increase the risk of failure due to increased leverage within the joint?

What additional strength if any is added by pinning joints?

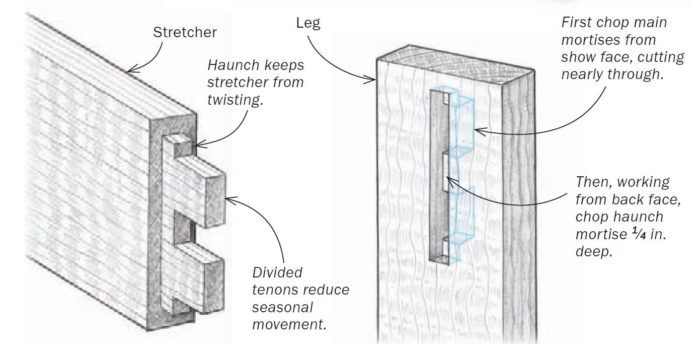

How much advantage is a haunch for resisting twisting?

Whilst I suspect that the real answer is that 'to all practical intents and purposes it does not matter' I find that intellectually unsatisfying.

Perhaps FWW might commission an article looking into the mechanics of various joints?

Log in or create an account to post a comment.

Sign up Log in