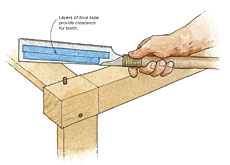

Flush Cuts without Scars

Finishing off through-tenons and joint pegs often involves crosscutting to trim them flush with the surface. The trick lies in removing as much of the waste as possible without marring the surrounding wood. For this task, some woodworkers favor a specialized “flush-cutting” saw with a flexible blade and no set to its teeth. In my experience, though, this type of saw tends to cut slowly and bind in the work. So I found a way to get great results using an ordinary flexible Japanese pullsaw with a normal set. All it takes is a little blue tape.

Simply apply strips of the tape in layers on one side of the saw so that their thickness slightly exceeds the set of the saw’s teeth on that side. The tape supports the saw parallel to the surface while lifting the blade just enough to keep the teeth from scratching the work. When applying tape, cover enough of the saw plate to create a reliable shim, but keep the tape clear of the teeth—3/4 in. away should be fine—to avoid interfering with the cut.

To make the cut, press the saw against the work, taking care to apply light downward pressure with your fingers on the taped portion only. Saw with a gentle pull stroke. The result is a clean, straight cut with very little waste left behind for paring.

Rob Porcaro, Medfield, MA

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Olfa Knife

Tite-Mark Marking Gauge

Log in or create an account to post a comment.

Sign up Log in