Q:

Is it possible to use a splitter with a zero-clearance insert?

Leo Chee, Southbury, CT

A:

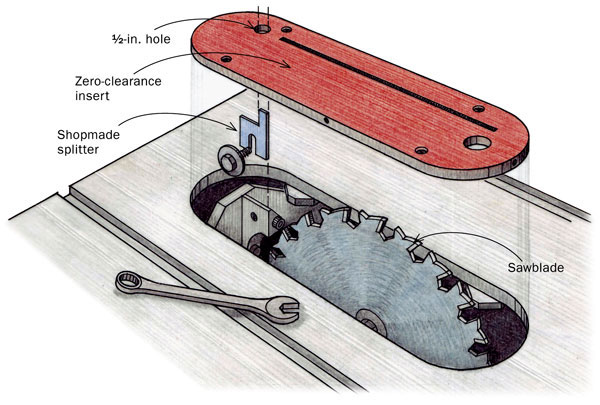

The long splitter slot at the back of a regular steel insert usually comes to within 1/2 in. of the blade slot. If you copy this in a zero-clearance insert made from phenolic resin, medium-density fiberboard (MDF), or plywood, the insert probably will crack. Instead, I drill a 1/2-in.-dia. hole through the insert close to the back of the tablesaw blade slot (cut at full blade height) and insert a smaller, shopmade splitter like the one shown.

I made this splitter from aluminum sheet stock that I bought for $7 a square foot (www.metalsupermarkets.com). Get the thickness that matches the kerf of your blade–0.100 in. for most thin-kerf blades, around 0.125 in. for standard blades. To cut the aluminum without damaging it, I attach it with double-sided carpet tape to 1/8-in.- or 1/4-in.-thick Masonite or MDF. I use a fine-tooth metal cutting blade in my jigsaw and it cuts like butter. Be sure to use a blade that can handle curves, and don’t use the orbital action on the jigsaw, just the up-and-down motion. I cut the mounting slot by drilling a hole at the top of the slot and then cutting two straight lines up to the hole’s widest points.

Like any splitter, this one is designed to prevent kickback, not accidental blade contact. So be sure to use it with a blade guard.

Drawing: Vince Babak; Photo by Charlie Reina

Fine Woodworking Recommended Products

Blackwing Pencils

Estwing Dead-Blow Mallet

Dividers

Log in or create an account to post a comment.

Sign up Log in