Making Raised Panels on the Jointer

As a high-school woodworking teacher, my students and I have been cutting raised panels on the tablesaw for years. It’s an altogether unsatisfactory method that at best is awkward, leaves burns on the bevel and doesn’t feel safe. In addition, the slightest tilt of the stock creates a cavity that is time-consuming to sand out.

I finally purchased a monster 5-in.-dia. panel-raising cutter for our large shaper. But when I mounted it and turned on the shaper, the combination of the gaping hole in the table and the helicopter noise of the cutter winding up to 10,000 RPM was enough for me to shut down the shaper without even a trial cut. There’s no way I would let students cut panels on this machine.

So, I was left with the same old alternatives: jigs for the tablesaw, radial-arm saw, router or wait a minute, why not the jointer? After a couple of encouraging but unsatisfactory prototypes, I finally found what I was looking for a safe, easy method that produces beautiful results.

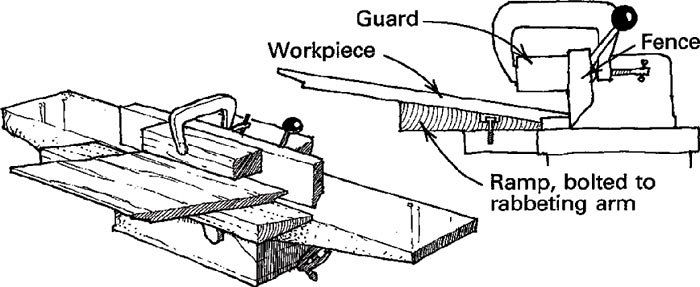

The key to the method is a beveled ramp that’s bolted to the jointer’s rabbeting arm. I make the ramp by bandsawing a board at a 10¡ bevel and then truing up the sawn face on the jointer. Take the time to ensure that the bevel is identical at both ends. Then, drill and tap holes in the rabbeting arm so you can bolt the ramp to the arm. Make sure the inside edge of the ramp is parallel with the fence and right over the left end of the knives. You have to remove the regular cutterhead guard to use the ramp, so install a wooden guard block on the fence as shown in the drawing. The width of cut is adjusted with the fence and the depth of cut with the infeed table. I found that 1/16-in. cuts produce good results. Just lay the stock on the ramp with its edge up against the fence and use a push block to run it over the cutterhead. Beveling the cross-grain ends first and then following with the grain will reduce tearout at the end of the cuts.

The bevel angle may be changed by making ramps of various angles or making an adjustable ramp. Some jointers might require different mounting methods, but the important thing to remember is that the ramp is mounted to the infeed table.

Joseph R. Robison, Freelandville, Ind.

Fine Woodworking Magazine, June 1990 No. 82

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Starrett 12-in. combination square

Ridgid R4331 Planer

Log in or create an account to post a comment.

Sign up Log in