Fortify Your Joinery

Hidden corner blocks add great strength where it's needed

Synopsis: Corner blocks are a simple way to add strength to a piece of furniture. Often you’ll find these small blocks glued behind bracket feet and crown moldings or under drawer bottoms or chair seats. Contributing editor Garrett Hack gives a primer on these easy to use but effective points of strength: what wood and glue work best, and how to place them where they’ll do the most good.

Repairing furniture has taught me many lessons about what joints, woods, and techniques survive decades of use. One technique I see often in well-made work is the use of corner blocks to strengthen connections or hold parts in position. Often you’ll find these small blocks glued behind bracket feet and crown moldings or under drawer bottoms and chair seats.

Corner blocks are simple, but for them to be effective, it’s important to choose the right wood, use the right glue, orient the grain direction appropriately, and allow for wood movement.

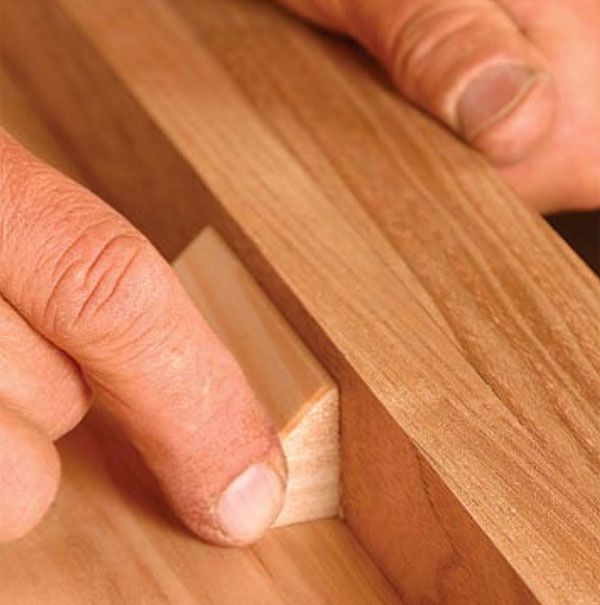

White pine, poplar, and basswood are my first choices for most corner blocks because they shape easily and provide adequate strength. For chairs, I prefer cherry, walnut, or mahogany blocks, which are harder woods but still can be fitted easily with planes and chisels. With the exception of an occasional brad or screw to hold a block in position, corner blocks planed to fit can be glued into place using a rub joint. Apply glue and rub the block back and forth until the glue grabs, holding the block in place—there’s no need for clamps. I use yellow glue because it is strong, grabs quickly, and allows a tiny bit of creep or movement. I try to orient the grain of the block in the same direction as the grain of the wood to which it’s attached, but sometimes one face of the block will be joined across the grain. In these cases, glue with a little flexibility is useful.

I think of corner blocks as points of strength, spaced apart from each other in much the same way as I use screws or nails. The short length of corner blocks, between 2 in. and 3 in., makes them easy to fit, especially when shaped into curved places. More important, compared with screws or nails, short blocks are less affected by wood movement in the piece to which they’re attached.

Blocks reinforce case-work joinery

Typical case-work construction is full of joints and other places suitable for corner blocks. I have seen case tops secured by corner blocks alone that are still holding after a century or longer. While I wouldn’t use corner blocks in this manner (too much potential wood movement on all but the smallest tops), they are ideal for reinforcing bracket feet, the knees of cabriole legs, or the connection of the base to the case.

Attractive bracket feet often are mitered at the corners with the grain running horizontally, making for a weak joint. Vertical-grain legs, as in the butternut chest on p. 50, are only slightly stronger because the glue surfaces of the miters are long grain.

From Fine Woodworking #176

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

MicroJig Matchfit dovetail clamps

Bessey K-Body Parallel-Jaw Clamp

Log in or create an account to post a comment.

Sign up Log in