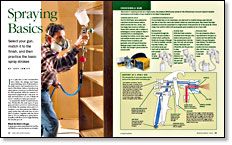

Spraying Basics

Select your gun, match it to the finish, and then practice the basic spray strokes

Synopsis: Lack of information is why so few woodworkers use spray finishing, says Jeff Jewitt. Makers of spray systems assume you’re already familiar with it, while manuals for entry-level equipment give only basics. Here are the main types of spray guns and how to match the gun to the finish. Different spray strokes will work best on each kind of surface. With this article, and its detail on how to spray various types of pieces, you’ll be finishing like the pros.

From Fine Woodworking #169

It’s a pity that so few woodworkers have taken the plunge and begun spray finishing. Lack of information is the main reason, and manufacturers bear much of the blame. Makers of professional spray systems assume you’re already familiar with spraying, while the manuals for entry-level equipment give only basic details, and instructions on cans of finish tell you to consult your spray-gun manual.

To remedy this dearth of useful information, I’ll describe the main types of spray guns and show you how to match the gun to the finish. By spraying various pieces of furniture, I can demonstrate the different spray strokes that will work best on each kind of surface. This information will allow you to begin finishing the way the pros do.

A spray gun mixes pressurized air and liquid finish in a process known as atomiza tion. For proper atomization, it is critical to adjust the gun to the thickness, or viscosity, of the finish you want to spray.

A viscosity measuring cup is small with a precisely machined hole in the bottom. Most turbine-driven spray guns come with this type of cup, but owners of conversion guns can purchase one for around $10. I use a Ford No. 4 cup, which is standard.

Viscosity is affected by temperature, so before you try to measure it, make sure the finish is at 70°F. Begin by submerging the cup in the finish, and then take it out. Start timing when the top rim of the cup breaks the surface of the finish. Raise the cup 6 in. over the can, and when the first break appears in the fluid stream, stop the clock. The number of seconds passed is the measure of the finish’s viscosity.

Once you know the viscosity of the finish, the next step is to choose the matching-size needle/nozzle and sometimes air cap. Keep in mind that the different styles of gun (gravity, suction, or pressure feed) use different-size needle/nozzles for the same finish. Always use the smallest needle/nozzle that you can, as the smaller-diameter ones generally atomize finishes best. Try thinning the product before you select a larger needle/nozzle.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Makita SP6000J1 Track Saw

Festool Cleantec CT 26 E HEPA Dust Extractor

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in